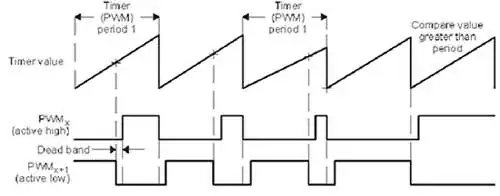

I'm having trouble understanding this concept, here is what the documentation in my microcontroller says about it:

dead bands are defined as the number of PWM clock ticks from the rising or falling edge of the generator’s OutA signal.

Google gives me this diagram, which helps a bit:

However, I can't see a purpose of doing this. What does it achieve?