First you need to pop up two levels in the overall design and ask why you really need 4 mil position accuracy. Even if you do achieve that most of the time, it will complicate inspection and lead to reliability problems. This smells like a a bad higher level design choice was made. Find out what the real problem is and then address it in a more reasonable way.

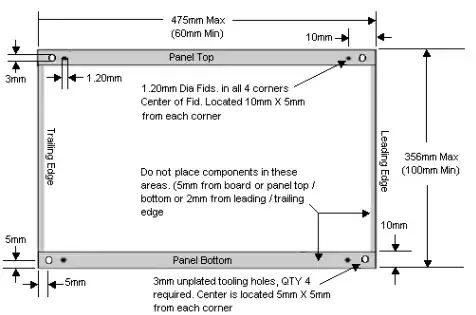

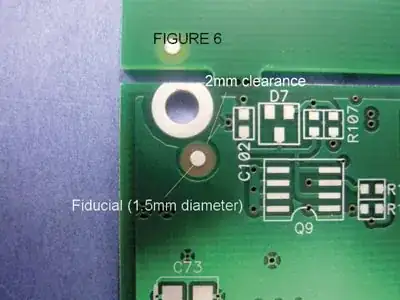

To get the best placement accuracy, you need fiducials as others have noted. Even when you don't put explicit fiducials on a board, someone at the board house will find two pads near the corners and set their system to work with that, right after grumbling something about "rookie" and "moron". Sometimes they will tell you they want fiducials, but usually they'll just cover up your mistake with maybe a little more position error and the aforementioned grumbling.

The best answer however is to talk to your assembly house. At that level of accuracy, you can't just slap a couple of fiducials on the board and figure everything will be fine. You need to have a dialog with them because different machines and processes have different capabilities.

However, even if the assembly house says they can do 4 mil accuracy and you do what they tell you to, how are you going to test this board? A manufacturing requirement is no requirement at all if it isn't tested to. Again, this gets back to my first point. The only right answer is to not be here in the first place. Not everything is possible or reasonable just because you can write a spec for it.

Added:

I meant to say this before, but got distracted and forgot before hitting send.

Even if the assembly house can guarantee original placement to 4 mils, that does not mean the part will end up there. Molten solder has a pretty strong surface tension, especially with respect to small parts (look up "tombstoning" for a extreme but real example). Once the solder melts, the original placement is largely irrelevant. The surface tension of the solder pulling on each of the pins will pull the part into the sortof "center" alignment. Usually this is a good thing since it allows for some initial placement error and still have the part end up in the right place.

In your case, this means the real placement is not so much a function of where the machine plunked down the part (this is the part of the process that fiducials help with), but where the pull of the solder surface tension on all the pads averaged out to. With a symmetrical chip and the pads only a little larger than the pin footprints, this is going to be pretty predictable. With a assymetric part, like a SOT23 transistor for example, this is not so obvious. The surface tension pull is also in part a function of how much solder got placed on each pad. So now the eveness of the solder paste thickness matters.

Again, what you are asking will be difficult at best, possibly unreasonable.