Sorry I have tried many google searches but can't find anything directly relevant.

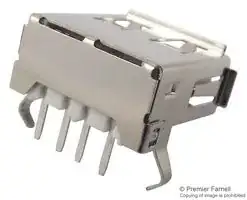

A USB Type-A female socket, through-hole, right-angle PCB mount has small 45-degree bent pins for soldering the shield to PCB. What should be done with these pins? Should they be pushed through a hole and bent over on the other side? Why are they bent to start with?