I've done quite a bit of searching online and can't find a solution to this (probably trivial!) problem:

I am looking to replace a resistive fuel level sensor in a car, with a solution which can be controlled digitally. A digital potentiometer is the obvious solution for this, however it doesn't appear that any exist which match the specifications:

Resistance range is 6-120 ohms. Current through the resistor during operation is up to 80mA.

The wiper resistance of most digital potentiometers is much higher than the 6 ohm minimum requirement. It seems that 80mA is also too much for most options. I have considered linking 4 or more digital potentiometers in parallel, but I'm sure there is a more elegant solution. I don't want to go down the "stepper motor and potentiometer" route unless I have to.

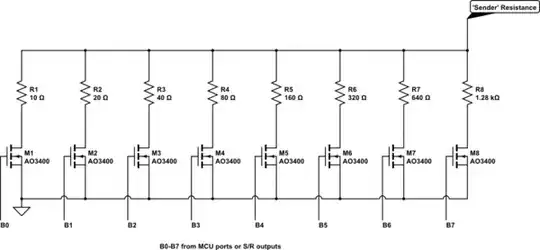

One thing I considered would be a resistor array, switched using transistors. These could be driven from a shift register, allowing suitable resolution without using too much IO on a microcontroller. After all, this is a fuel gauge, it only really needs 16 levels to be functional.

I imagine that having 7 transistors, each switching a resistor, with values of 1,2,4,8,16,32,64 ohms (or similar), it would be possible to create such a circuit. The issue is how these transistors will react when combinations of them are switched. I can't quite get my head around how to design such a circuit.

Does anyone here have experience with such a circuit? Is there a "cleaner" alternative?

Thanks for your time!

In the image below, L1 and L2 are the motor windings, R5 and R6 are fixed resistors, L7 is the potentiometer to replace.

I guess I should add that this "digital resistor" is driving a fuel gauge directly. The gauge is a pair of motor windings, it appears that one receives a constant voltage, and the other is varied using the potentiometer as one side of a potential divider. These two coils each want to move the fuel needle in opposite directions, they seem to "fight" each other, and the whole affair ends up rotating to a position determined by the strength of the adjustable winding.