That solder fume extractor not only does not perform any filtering of particulates, but it also doesn't perform any filtering of dangerous VOC. It is not possible to compare particulate & gas pollutants by mass, as their mechanism of toxicity is different.

In order to capture any significant amount of dangerous gasses, you need a significant mass of activated charcoal to adsorb the chemicals, as well as to change the filter as it becomes saturated.

Disclaimer: I'm not an occupational health specialist or a chemist. I expect my calculations to be correct within about an order of magnitude, and no more.

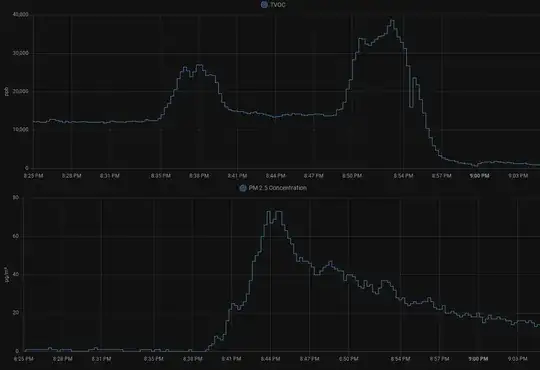

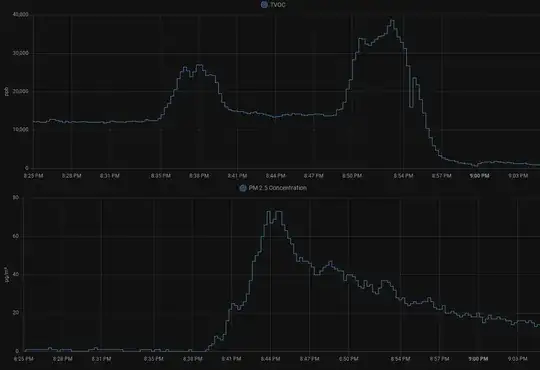

To calculate exactly how dangerous the gases are, here is one of my soldering sessions. I'm indoors, and I have a HEPA filter but no significant VOC filtration, and my readings are from a SGP30 VOC sensor and a PMS7003 particle sensor:

I start my soldering session at 8:35 PM, and finish up and open a window at 8:52 PM. Ambient air quality was pretty crummy to start with, but my soldering caused the VOCs in the air to climb from 12ppm to 38ppm.

It's unclear what exactly the chemical compounds that make up soldering fumes are, and it depends heavily on the exact type of flux. An Investigation Into The Composition of Solder Fume suggests that about 26% of fumes are some sort of aldehyde. These aldehydes are split about 50:50 between formaldehyde and acetaldehyde. With these rough numbers, and the (IMO, likely too permissive) occupational limits:

┌──────────────┬────────────────────┬────────────┬──────────────────┐

│ compound │ est. concentration │ 8-hr limit │ short-term limit │

├──────────────┼────────────────────┼────────────┼──────────────────┤

│ formaldehyde │ 3 ppm │ 0.75 ppm │ 2 ppm │

│ acetaldehyde │ 3 ppm │ 25 ppm │ 25 ppm │

└──────────────┴────────────────────┴────────────┴──────────────────┘

My soldering task exposed me to unsafe amounts of formaldehyde. My exposure was likely dramatically higher because I was next to the work while the sensor was in the middle of the room.

I was also exposed to a wide variety of other chemicals, but the health effects of these chemicals are not well studied or regulated.