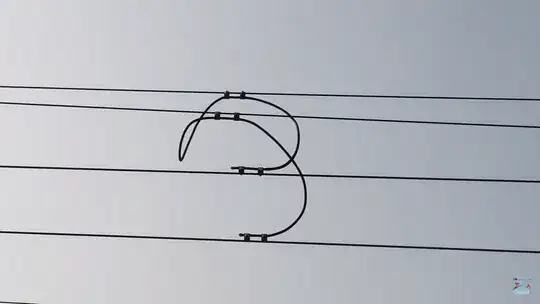

Double connections avoid torsion stress on the connection points. A single connection would allow the jumper wire to rotate w.r.t. the overhead lines around the connection point in the presence of lateral forces, which would tear the metal apart.

With the double connection point, rotation is no longer possible. Instead, lateral forces would create tension in one point and compression in the other one, and metal parts withstand tension stress much better than shear stress than the rotation would produce.

The extra length of the jumper allows the overhead lines to move independently, so that the presence of the jumper has minimal impact on the longitudinal waves in the lines. Such waves appear as the train's pantograph moves along the line at high speed. A hard join would create a reflection point which would result in (ideally) a double amplitude in certain parts of the wave, which could be enough to wrap the overhead line around the pantograph and thus destroy it.