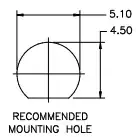

Wouldn’t a circle shape be simpler to design?

If your benchmark is the number of geometric primitives? Sure. But when the difference is between 1 primitive or 2, and you don't scale them to millions in number on the same design, then it doesn't matter whatsoever. Yeah, the circle is "simpler". So what?

Drawing and dimensioning a circular hole takes say 30 seconds. A D-shaped hole may take what, twice that?

And even if this was AutoCAD in the 80s on an XT-class 8086 machine: it would not take much longer. Been there, done that :)

If you want to make it totally painless, add the shape to your favorite CAD's feature library, so you can just "stamp it" anywhere you want quickly.

With mainstream feature-based 3D CAD, to get the shape from scratch you create a sketch, draw an arc, connect the ends with a line, add a couple of constraints and dimensions, extrude the D-shaped face from the the sketch in subtract mode, done. Or the hole feature may already have that shape baked-in. Depends on what platform you're on.