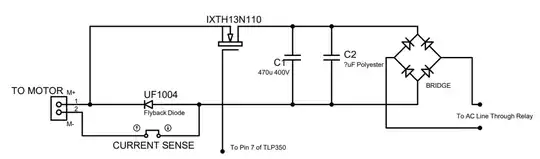

I am trying to repair a treadmill PWM controller board.

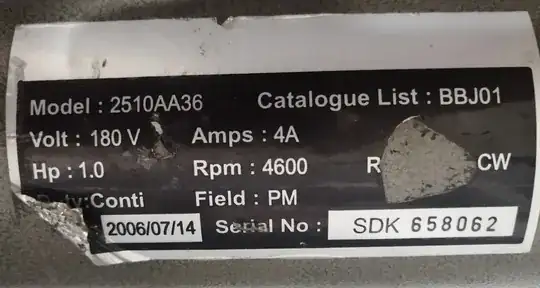

The power MOSFET (IXTH13N110) is burned out completely with all 3 pins are shorted, and as it's a bit expensive, I can't risk to replace it and test.

I removed the burned out MOSFET and checked the gate to source voltage using an oscilloscope, without any MOSFET installed. I simulated rotation sensor using a variable frequency 555 timer. when pushing the start, it counts down and then a gate drive signal is read on oscilloscope (Vgs); with frequency of 15 kHz, Vgsmax of ~11 V, and duty cycle of <1.3%. When I increase the speed using panel, the duty cycle does not change, and it just increases up to ~90% until I increase the frequency of simulated rotation sensor. then the duty cycle returns back to <1.3%. In any speed selected on panel, the duty cycle is either <1.3% or ~90%. As far as I know, by increasing the speed, the duty cycle should increase to increase the motor speed. But that is not what I get on oscilloscope.

I also replaced the original MOSFET with different one (22N60) to test the result without motor (as I am using a ~2 kVA isolation transformer to power up the board and also not mounting the original MOSFET due to the price), but it burned out just after triggering.

Does mounting new identical MOSFET result in correct response?

Is there any way to test without installing new MOSFET?

As the voltage at motor terminal will not exceed ~320V (At worst case), may I use a 600V MOSFET instead of 1100V?

UPDATE 1

I checked the power section tracks, and the flyback diode is also OK.