I have designed and then manufactured a a PCB that is basically a WiFi thermometer with MQTT capability. The PCB hosts several components, plus an 18650-type battery holder capable of holding 2 batteries and it should also host a 2S battery management system (BMS) for managing the batteries. The BMS is actually a "prefab" PCB such as  .

.

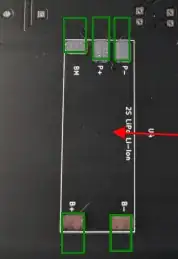

Here is a picture of my PCB (black) with the prefab 2S BMS PCB (blue).

What do I need to do?

I need to solder the blue PCB directly to the black one on the corresponding pads (B+ with B+, B- with B-, etc.,) but I am having some issues.

What have I tried?

Firstly, I have melted some soldering wire on the pads of the black PCB (B+, B-, BM, P+ and P-) then tried to solder the blue PCB to the black one with a "classic" soldering iron (bad idea.) Secondly, I tried doing the same but used a hot-air gun for soldering (somewhat better results but very prone to damaging the components of the blue PCB or the tracks of the black PCB.)

In the end, I simply didn't install the prefab BMS.

- What would you recommend for successfully soldering the two PCBs together?

- Do I need to resort to a SMD reflow oven or SMD hot plate?

I have found a similar post (this one), but it makes use of "castellated holes" (sort of) and thus it is of no use to me.

A couple of closing notes:

- Sorry for not posting the picture of my PCB directly on this post, I have received a server error from Stack Exchange side.

- I know that the 2S-BMS PCB should be soldered with a spot-welder to nickel strips, but I didn't want to do so on my PCB.