I'm planning on building another LED cube. I've built ones before using tinned 0.6mm copper wire which looked OK, however the wire bent easily and was never quite straight in the first place.

I spent a long time searching for some sort of stiff, straight wire to use for the structure of the cube, however couldn't find anything suitable (somewhere around 1mm in diameter and at least 250mm long). I realise this may be off topic, but is there a specific type of wire I can find that is pre-straightened and (shiny) silver in colour, that's solderable using conventional methods?

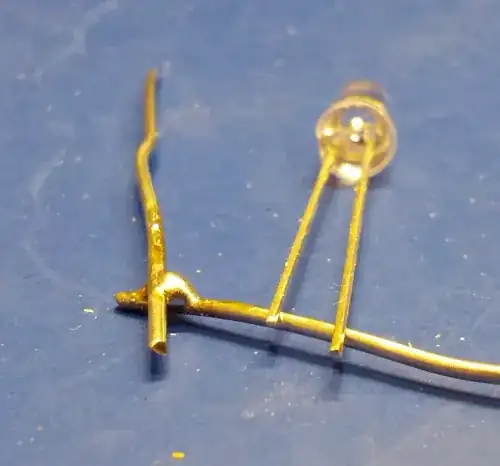

The type of wire I'm looking for is similar to LED leads like this (but stiffer):

The makers of the Hypnocube suggest using 22 AWG straightened galvanized soft steel wire in their build instructions, however long searches on the internet and eBay revealed nothing.