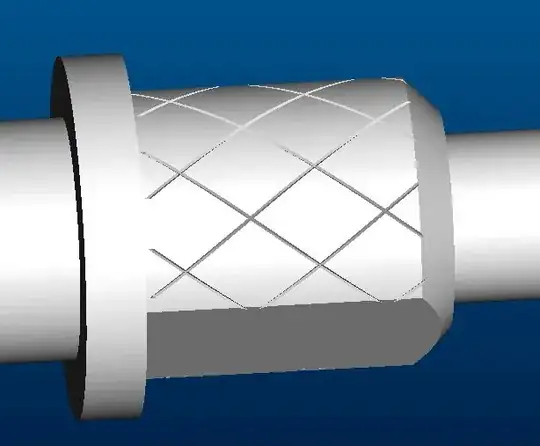

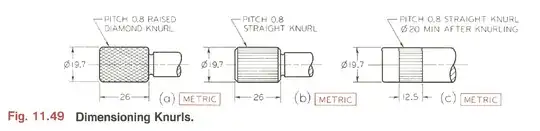

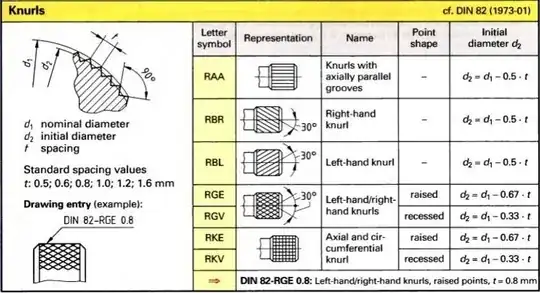

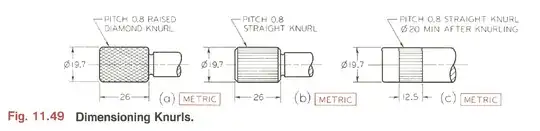

It looks to me like your guess was pretty good. The required information is only the type of knurl, the extents of the knurl, and the pitch. It is conventional to show the representative pattern, but not necessarily in true scale or projection. The following images are from a technical drawing textbook (Giesecke et al.):

It goes on to specify that this is enough information for hand gripping purposes, but if the knurl is intended for a press-fit, a minimum diameter after knurling should be listed. This insures that there is enough upset formed by the knurling process to assure your press-fit is secure. In this situation it is obviously also important to include the toleranced diameter of the part before the knurl is applied.

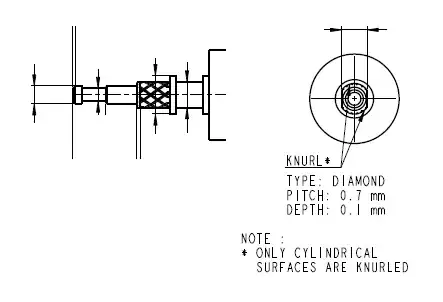

I would not recommend calling out the depth of the knurl. The machinist will likely have to adjust this as it is the only option they have to make sure the pattern aligns with itself on successive revolutions. At the most, I would specify a minimum depth, but not a target depth or a maximum depth.

As a matter of style, I would recommend calling out the knurl on the face view, not the end view so it is more clear what it references. Additionally it may be hard for a machinist to knurl right up to that shoulder on the right of the knurled area. If you could hold the knurling back even 1mm that would probably help. You can probably safely assume that the machinist will know to only knurl the cylindrical faces, not the flats.

In the US, ANSI B94.6 has a tolerance class system to ensure that the pre- and post- knurl OD tolerances are compatible, but I haven't seen any reference to how it handles metric units like you have.

You can find a little more information on knurls and how they are calculated and formed in the Machinery's Handbook machining section, but it is very inch-centric.