I would tend to agree with Chris Johns on this one - it's probably not a great use of your time and may not provide satisfactory results - but that's not what you asked...

To directly answer your questions:

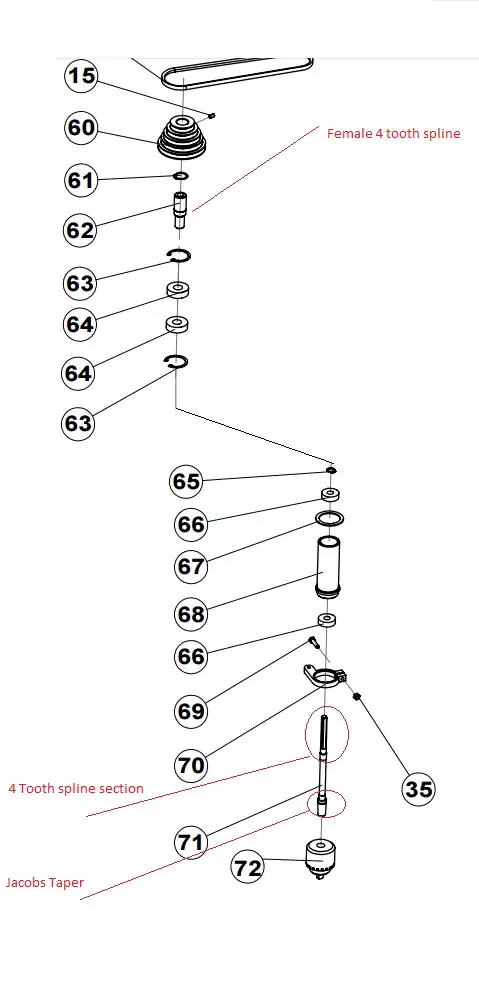

Are there any solutions for coupling or attaching a spline shaft to a plain old shaft? What is it called and do they exist?

Yes, there are. A press-fit, or interference fit, may be a suitable means of attaching the two components.

If you're not familiar with the concept, a press fit (aka interference fit) means you press a pin into a hole that is slightly smaller than the pin (creating interference between the components which holds them together). In the case of metal-to-metal were talking a size difference of few tenths' of a thousandth of an inch [.0001] to a few thousandths [.001] of an inch.

If you provide more information regarding the materials of construction (presumably some sort of hardened tool steel for the shaft, not sure about your collar) and actual dimensions (actual meaning you measured the parts with a micrometer, or other suitable measuring device, and not the nominal dimensions provided by the manufacturer or parts description) then you could use an online fit calculator such as this one provided by Engineers Edge to get an idea of the interference needed - maybe look to the FN5 class for example.

I'm suspecting you're going to need a significant interference to withstand the loads expected, so you'll probably need a hydraulic press or a good source of heat, or maybe a combination of the too.

Again, if you know the material of construction, you can use the coefficient of thermal expansion to determine the temperature change necessary to cause the female member to expand large enough to slip the male member in, and then when it cools and contracts it will create the interference necessary to hold the parts in place.

Another option you might consider, is that you can press fit the pieces together (I recommend the shrink fit method above to maintain concentricity) and since this is a splined shaft fitting into a round hole, you may be able to braze the shaft to the coupling (filling in the gaps in the teeth with brazing material) which would be extremely strong. Again without knowing more about the base materials I don't know if this is a suitable suggestion, but it's worth considering. Many cutting tools used for milling operations which have carbide inserts are brazed, and it's proven to be a reliable and strong connection for the job.

Standard disclosure: you should consult an engineer experienced with this type of application (someone specializing in machine design, or machine maintenance might be a good place to start) before taking numbers off some website or the words of some guy who doesn't have all the information about the application. For one - the numbers suggested on the site I linked to are based off an ANSI standard that provides recommendations for common applications of holding a round pin in a round hole - none of which describes your application. And for two - you're playing with some pretty large forces and heavy loads in a milling operation, and a catastrophic failure could send an extremely sharp large chunk of carbide, cobalt, or high-speed-steel straight at your face, eye, throat, or child-rearing organs which would not be very fun at all.

Finally, I am not completely married to using a spline drive mechanism in order to extend and retract the quill, so I welcome any suitable alternative mechanisms. I saw a ball spline, but wasn't sure if it works the same way as the existing mechanism.

Bridgeport mills typically use an R8 quill.

I don't know if it's feasible, but if you're going down this road you might look at adapting one of these to your drill press.

Lastly - my personal opinion only - is that the amount of time and money you'll spend on this project, which may or may not have a good outcome, is not going to be worth it. Have you considered just purchasing a used bridgeport (or cheaper chinese knock-off) mill? I'm not sure where you're located, but I just did a quick search on craigslist and in my area there are at least 5 ad's for 2500 USD or less, and a couple for 1200 USD or less. I would seriously consider what you want to do with your mill, and decided when it's worth spending the money on a proper machine, and until then, you can always outsource your milling work to a local shop or even an online company like rapid-machining.

Best of luck to you!

-Steven