We have an extended Chevy express with a 24" high-top, on which we intend to install roof-mounted PV.

I'm really concerned with how to properly install the panels. We've selected six 100 W Renogy panels and a 400 Ah LiFePO4 battery pack, but it might be too much for our roof. I'm worried that if we are going 80 mph up I-5 and hit a 40 mph cross-breeze we could tear the roof off the van, rip the panels off the roof, destabilizing and roll the vehicle, etc. How can I avoid or minimize these risks?

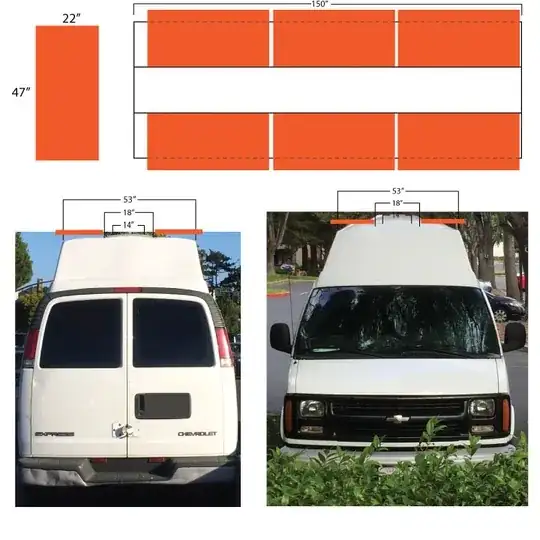

I was initially thinking of laying three panels long-ways on each side of the van, with a ~20" section down the middle I can walk down and hang out or service the panels, and where the roof vent will go. Each section then would only be 22" wide (140" long) with space on both sides for air to dissipate to either side.

My plan is to build my own rack with bent heavy conduit and bolts. The rack should be pretty strong. But could unwieldy pressures blow out the panels? I don't know what thresholds they should withstand. The product shows 2400 Pa high winds and 5400 snow, but what does that correlate to in driving down the road?

You'll notice that with the current layout, the panels must go over each side by 4.5 inches. To me, this means they can be more affected by wind. If the roof was just flat instead of the bubble top, mounting might be much easier.