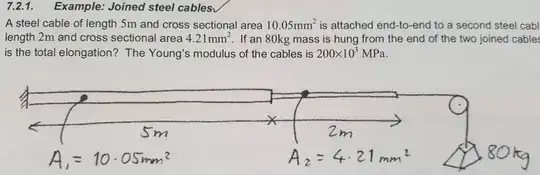

I am sorry if this question has been asked before or if the answer is obvious, but I cannot seem to find the answer. A lot of the structural engineering problems we do involve calculating the elongation of certain types of beams/cables etc while under tensile stress. In particular there was a relatively straightforward question that asked for the total elongation of a structure comprised of two connected steel cables which have different cross sectional areas. Each of the two cables had consistent cross sectional area, and the structure was placed under an axial load of 800N.

I am sorry if this question has been asked before or if the answer is obvious, but I cannot seem to find the answer. A lot of the structural engineering problems we do involve calculating the elongation of certain types of beams/cables etc while under tensile stress. In particular there was a relatively straightforward question that asked for the total elongation of a structure comprised of two connected steel cables which have different cross sectional areas. Each of the two cables had consistent cross sectional area, and the structure was placed under an axial load of 800N.

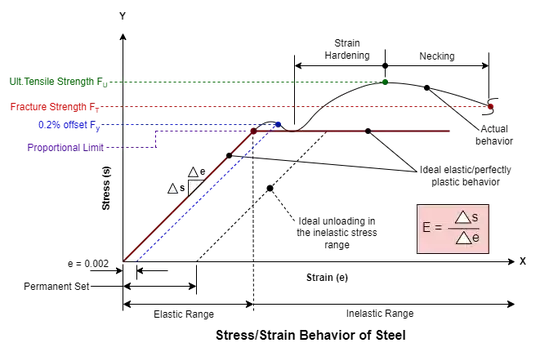

Solving for the total elongation was simple with delta = (FL)/(EA) for each cable and adding the two deltas. My confusion however is with why this is considered the total elongation.

After the structure has undergone this elongation, it will become a 'new' structure, with a different length and different cross=sectional area for each cable. My question is, if the load continues to be applied after this 'initial' elongation (delta1+ delta1), then wouldn't the new structure still be under direct stress, and thus based on the new E of each of the now deformed cables, would each deformed cable undergo deformation again? And would this process not repeat until the object yields?

I understand that in tensile testing a specimen's stress-strain graph will be obtained by deforming the specimen until it has yielded. This is why I am confused because under load, would these cables not just deform until they yielded? And if so, wouldn't total elongation then be based on the final length just before the yield point?

Edit: The two steel cables in the questions are connected together, with the cross-sectional areas of the two cables being distinct, i.e. a smaller circle stuck onto a larger one