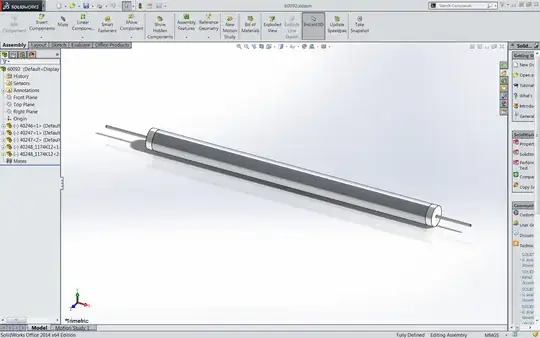

I'm working with some flexures (circularly symmetric tube with pins at the ends). Their bending stiffness matches my FEA. However, I'm concerned that they are buckling, reducing their overall axial stiffness.

I don't have a way to measure the axial stiffness in situ; the flexures are part of a larger system.

I don't have a lot of mechanical measurement equipment either, but I do have:

- Accelerometer

- Laser distance measurement device

- Oscilloscope

- Masses, scales, ...

I can model the buckling, but the rest of the team relies on measurement and doesn't believe models. So, I need to come up with a method of measuring buckling of the flexure in compression.

Ideas?