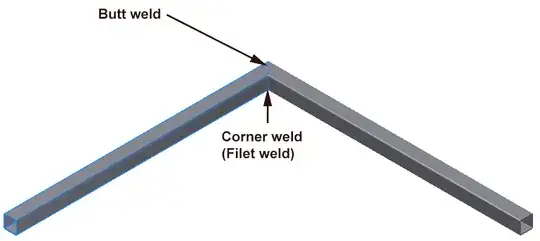

Assuming you're talking about plates: it would depend on you code, but usually it's the angle between the two joints that matters. If you mean a 90 degree joint with two 45 degree miter angles, I would still treat it as a corner joint. If there is a 10 degree miter angle on each piece so the dihedral angle in the joint is 160 degrees, it would be considered a butt joint.

In AWS D1.1 for example, the notes of table 3.3 specify that and dihedral angle from 135-180 is a butt joint and any dihedral angle from 45 to 135 can be considered a corner joint. In the 2008 version of the code it's note j - I don't have another year handy to cross reference. Note that in some scenarios you may need to account for a Z loss factor on the acute side.

If you are talking about tubes, this is significantly more complicated and we'll need more details, especially what type of tube and what code you are working to.

In reference to your edit that this is a tubular mitered L connection : I believe the proper thing would be to specify a PJP weld around the two flat sides and the outside corner and a fillet on the inside corner. For the purposes of weld qualification, the two flat PJPs would be considered butt welds and the outside corner would be considered a corner weld. This might mean that you want to provide different bevel types at each side. It is also acceptable to specify a PJP weld on the three sides and allow the contractor to chose the bevel type that is best for them as long as they obtain the effective throat you list (or the code minimum)

The following is from the FAQ at the steel tube institute.

QUESTION:

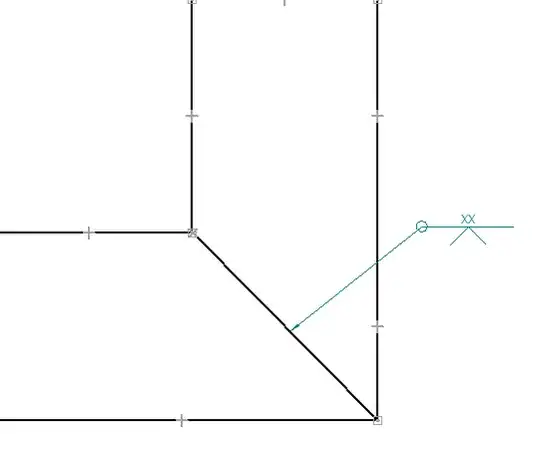

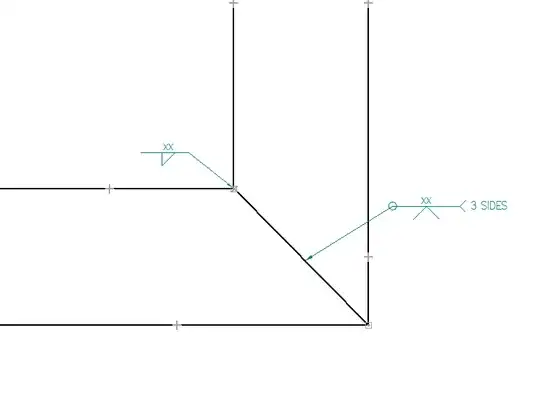

Are different AWS D1.1 prequalified welds required around the perimeter of a 45o miter butt joint used to connect two pieces of HSS at 90 degrees? Or, can the same weld be used around the entire perimeter? In either case, what is the prequalified weld typically used? A partial-joint-penetration groove weld?

ANSWER:

In direct answer to your question, edge preparation (beveling) of the HSS would be required along 3 of the 4 edges of the miter joint, in order to successfully accomplish PJP welds along those 3 edges.

The capacity of such welds is limited, and the welds themselves (to matched box sections) need to be made very carefully. For such miter joints, especially if there is reasonable applied loading on the HSS members, it is recommended that the two HSS each be separately welded (usually by fillet welds) to a 45o stiffening plate. This type of “knee connection” is shown and discussed on pages 67 to 69 of CIDECT Design Guide No. 3 – “Design Guide for Rectangular Hollow Section (RHS) Joints under Predominantly Static Loading”, 2nd. edition, 2009.

I'm not familiar with euronorms, but I imagine they would be similar since the underlying principles are the same.