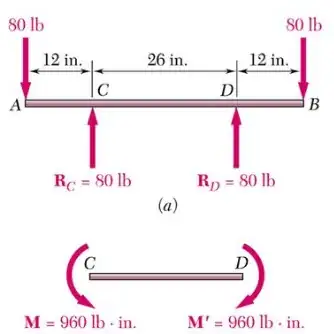

I have a beam experiencing a pure bending moment. The setup is similar to this image from these lecture notes (with different values).

Using the flexure formula, we can determine that the stress (and thus the strain) at any point along the top of the beam between C and D should be the same: $$ \sigma_{max} = \frac{Mc}{I} $$ where $M$ is the moment, $c$ is the distance from the neutral axis, and $I$ is the area moment of inertia.

However, I've a couple of strain gauges along the top of the beam measuring strain in the axial direction. These gauges are reading different values at different locations between C and D.

Is this expected? Is it a limitation of the model or are the gauges malfunctioning (or laid up improperly)?