I'm trying to design a mobile robot which has to climb over flat 60° inclined wet glass surfaces.

I was thinking to use a large vacuum system composed by a large fan connected to a brushless motor. By looking on google, I found this photo:

As it is possible to see, they use a brushless motor with a fan to generete some kind of vacuum to keep the robot on the wall. This system is very similar to the RC wall car toys which are able to vertically move on flat walls.

My idea is to create a vacuum chamber and to make it connect to the surface by using a soft rubber gasket (to avoid leakage), but I do not know how to design the vacuum generator.

- How many RPMs do I need?

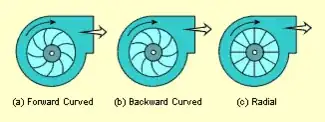

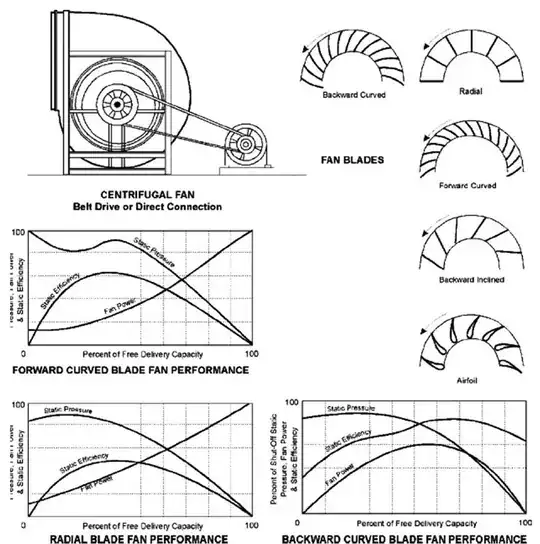

- What shape should the fan have?

The robot has a weight of about 30-35Kg and its size is 1000x800 mm. The surface which can be used for the vacuum generator is the space between the tracks and it is about 800x600 mm.

I hope you can help me!

Thank you a lot!

EDIT 2 Information after @ericnutsch answer.

This is my ideal design.

I would like to use a cylider as case for the fan/impeller, use a rubber gasket for the cylider borders in order to avoid leakages (when possible). The cylinder/case will be suspended by springs in order to make it touch the surface by using the weight of the chassis. I do not know if the drawing is clear, but this is what I would like to acquire. The dimensions showed in the figures are realistic and the weight of the robot is about 30-35kg.

EDIT 3

on #Mark answer:

I've found this impeller which can be customized and can have a diameter of 550 mm. It comes with some specifications:

EDIT1: This is what I tried so far:

During last months, I did several tests with different solutions:

- Using rubber tracks with Linatex which offers a great grip over flat surfaces

- Multiple suction cups with a vacuum generator

The Linatex works very great up to 60° if the surface is not wet, if it is wet, they works fine up to 18°.

The 4 suction cups works fine only if the robot moves very very slowly (0.1 m/s) otherwise they lose the vacuum.