I'm interested in whether a flat rubber washer or equivalent is good enough to replace an o-ring in a low pressure application (edit: I meant low pressure differential. My bad.). The reason is that flat washers might be easier to design for if you have a dynamic seal application where one tube has to "air lock" against another tube.

The application is to mount an air sampling tube in such a way as I can automatically sample air and then, later, automatically heat the tube to 200C and pull the vapours.

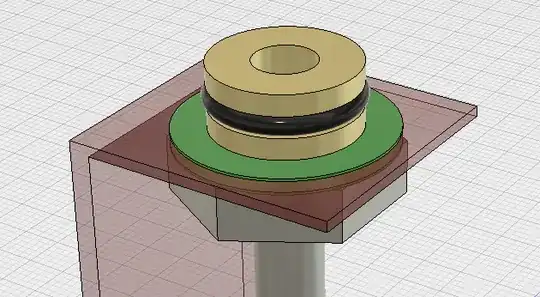

The tube is just a thin walled (0.25mm) steel tube 6mm or so in diameter and 40mm or so long). Here's how I initially imagined the system:

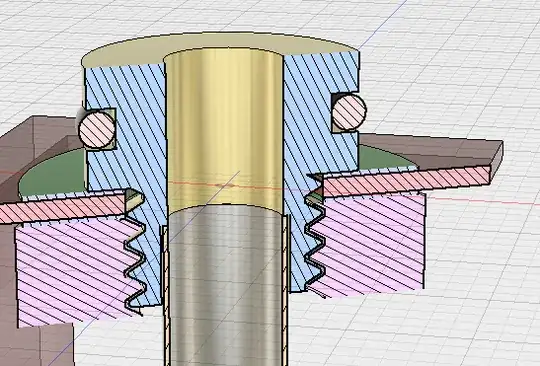

So some sort of automatic airlock connector tube could move out, seal against the o-ring and then stop at the green washer. The green washers might be something like mica or teflon, something able to take the 200C while insulating the holder - I want to heat just the tube, not everything connected to it! Here's a cross section:

I have some issues with this - firstly I'm not convinced that a metal to metal seal (tube against holder) will air seal properly, even when pushed by the automatic connector. Perhaps another o-ring is necessary?

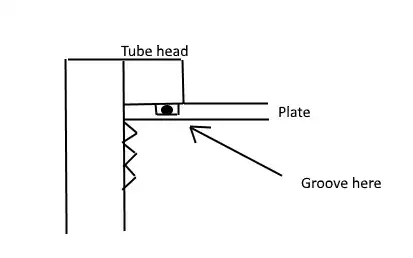

Secondly, mica washers aren't flexible (I think) and getting a washer into a groove like I've shown might not be possible. If I replace the washer with some form of flat seal which captures itself against a lip, perhaps this type of form:

As I would have to make the connector by machining or other process, perhaps this would make the design easier. But is such a v type seal effective at air sealing? The difference is that in the O-Ring, positioning is all that is necessary but with a flat washer type, you need force too (related link: What are the common failure points of waterproof cases?)

EDIT: Clarifications:

- I believe I tried to present too much information at once and missed the important points!

- The pressure differential should not be very high. I'm considering a flow, from outer atmosphere, of a few litres per minute through a sorbent. If the pressure diff was more than 1/2 atm I'd be surprised.

- The green washers are really to provide heat isolation, not air sealing. If the sorbent tube is 200C I didn't want the entire system to try and be 200C too!