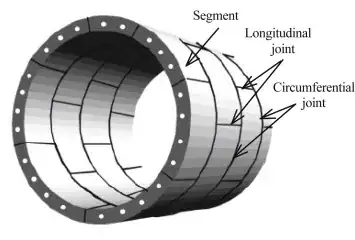

Hy everyone :) I don't know much about structural engineering, maybe spiral lining and cylindrical lining are not the proper terms - but take a look at the pictures below to understand what i mean.

I need help to form some intuition about which one of this 2 is better for lining a tunnel. I want to know specifically about earthquake resistance And also other important factors which play a role in choosing between this 2 designs - factors i'm not aware of right now.

I couldn't find a proper spiral lining image - this just gives you an idea - but let say it was a proper lining with joints and such - like the cylindrical one has.

Assuming that the spiral components will be connected in the most practical way possible - and assuming they have the same wall thickness, same concrete composition, etc.. which one is better?

Will they behave the same under stress ? Or the cylindrical one is better ? But why?

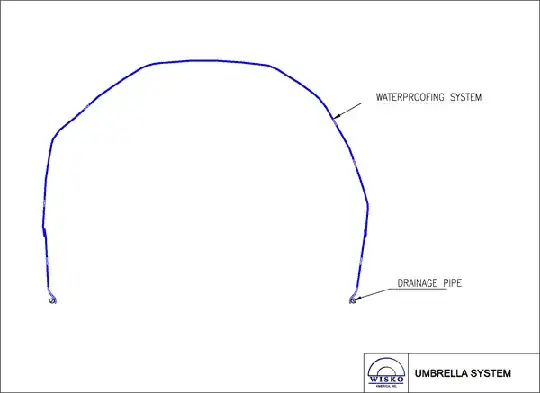

And also i want to understand how a cylinder compares with this shape in terms or resistance..

Which one of 2 geometries ( cylinder or arch ) is most effective for preventing damage in case of earthquakes, or just in general ?

Explanation: - why i'm interested in this?

I want to find the drawbacks of spiral lining. I think that from a construction perspective spiral lining is better - because can be constructed continuously.

By contrast, if your TBM moves fast enough - the cylindrical lining requires stopping of the hole machine - to insert each segment all at once. And then another cycle begins. This takes valuable time. Time that can be used for drilling.

For increasing tunneling speed - i think spiral lining has this amazing advantage - will not require stopping.. you build as you go, smooth and continuous.

But i don't want to trade safety for tunneling speed. I want to understand if spiral lining is actually viable.

Maybe i'm wrong about this stopping, but that's another topic :) Let's keep this discussion only about geometry for now.

Thank you, and have a nice day!

Disclaimer: With input from Solar Mike, i will add this disclamer: neither of this images are mine, Tunnel image is taken from here: http://www.sciencedirect.com/science/article/pii/S1674775515001195 Spiral image is taken from here: http://www.sunshinecoastformatubesupplies.com.au/spiraltube-steel/