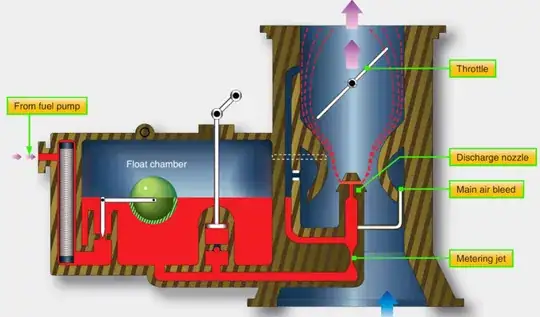

I'm confused on how to differentiate mixture control from the main metering system, and why we even need one at all. Let's say we had a large resovior, and a needle type mixture control system. The differential pressure would push/pull fuel from the discharge nozzle at our set mixture ratio? Then where does the need for the main metering system come in?

Any help is appreciated, thank you!