You're probably thinking, "Well.. Why not? It's gotta be something.." Right?

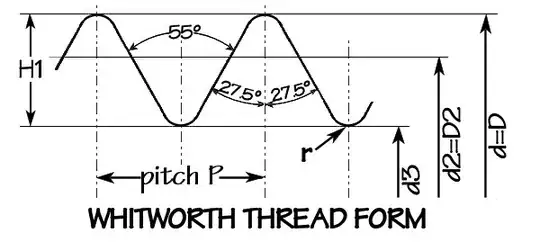

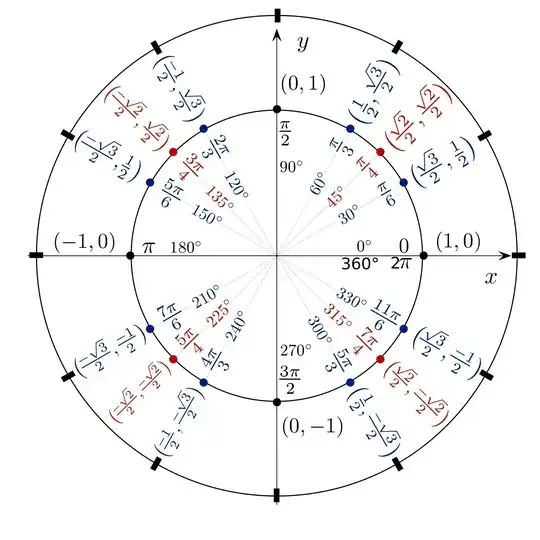

But 55° is kind of an odd angle if you think about it.. and it does seem like a pretty specific choice considering a perfect equilateral/equiangular triangle consists of 60° angles. Wouldn't 60° be the default/simple/obvious choice for a triangular profile? Wouldn't it have been easier to manufacture? It seems like 60° would at least be the most logical starting point (like starting at zero) during the design phase. Or any other common, suitable, trigonometric angle; i.e. 30°, 45°, even 90°.

Also, Whitworth strikes me as a pretty meticulous, character; detail oriented, with a careful consideration for all aspects of his designs. Plus, when it comes to mechanical engineering, he has a history of favouring experimental & unorthodox geometry.

Also, Whitworth strikes me as a pretty meticulous, character; detail oriented, with a careful consideration for all aspects of his designs. Plus, when it comes to mechanical engineering, he has a history of favouring experimental & unorthodox geometry.