Water is going to have to leave the turbine at a speed. That what you've referred to as its residual mechanical power. The thing is, the turbine has already slowed down the water as much as can reasonably be done, while still allowing the water to leave the plant and not flood it. So slowing it down further with an extra stage of turbine just isn't an option. If it could be slowed down further, then the first turbine would be designed to do that.

There are examples of turbines in series: there are rivers with more than one run-of-river hydro plant.

But for most storage hydro, it's simplest just to extract as much of the kinetic energy as you can in one go. It's fewer things to maintain and manage. Chaining them in series would just reduce the energy available for the downstream turbines.

Ultimately, the energy you can retrieve is limited to height of the drop times weight of the water (times g, gravity's acceleration), minus the kinetic energy of the water upon leaving the plant. (It can't leave with zero kinetic energy, as zero kinetic energy would mean that it didn't leave the plant at all).

Adding more turbines has no effect whatsoever on that equation. If the drop's the same, and the mass of water is the same, and the speed of the water leaving the plant is the same, then the amount of energy harvested is the same (assuming constant turbine efficiency).

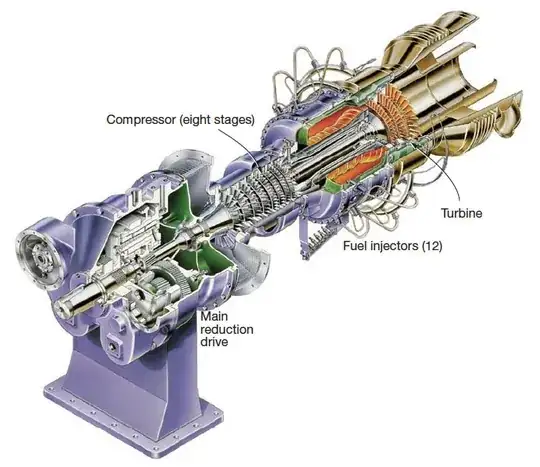

I think, from your question, you're wondering why a hydro plant isn't more like a CCGT, with its multi-stage turbines. A hydro plant is much simpler, more efficient, and more effective than a CCGT. A CCGT has its complications because it's a thermal plant with highly-compressible fluids and a phase transition (water to steam). A hydro plant is just harvesting kinetic energy. A cascade of turbines doesn't offer anything other than complications to a hydro plant.