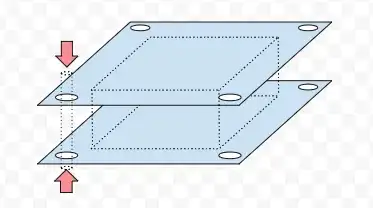

I am designing something with a sandwich construction that needs to squeeze the internal layer uniformly. The lower plate is to be made from cast iron and the upper plate needs to be made from copper. The squeezing will be done with four threaded rods, nuts and some spring washers.

The squeezing force I need to apply is 30720N, so I guess 7680N per nut (or is it not so simple?). And what I really don't know is, how do I determine a thickness of material required, given its properties and my design details? My requirements are

- Plates will not deform like playdough between 20˚-150˚C

- Plates will not buckle like a spring very much, so that the sandwich pressure is not applied unevenly.

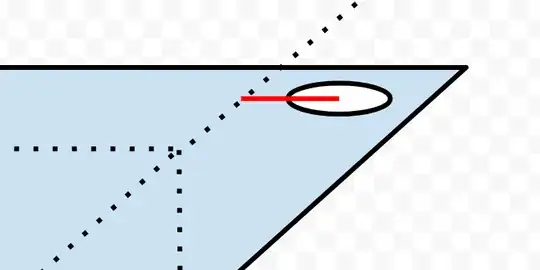

kamran's answer describes the red line below as the lever distance in his model.

I have tried my best to read up on Young's Modulus and Shear Modulus, etc., but I do not grok how to correctly apply these to real life.

Question: Can someone kindly point me to a formula or a workflow so that I can calculate the answer myself?