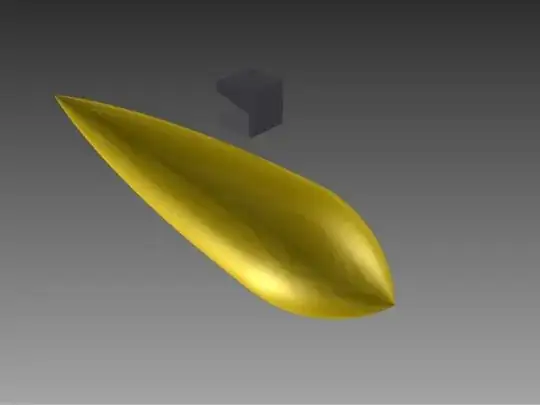

We all know the typical streamline shape which looks like a tear. But what is the optimum shape (for speeds 0-200 km/h)?

Is the front a half sphere or is it an ovoid? How are the sides and the end formed? Can it be described in a formula or in a bezier curve? What is the drag coefficient compared to standard tear drops? Image with explanations how the shape must be built to minimize the drag are perfect.

And no, I don't accept flat plates and perfectly laminar airflow :). The shape must be built around a pipe with diameter R and must not be longer than 10R.