I aim on building a silent, completely passively cooled PC, with no moving parts at all (I am aware that it is cheaper to go for an inaudible computer instead, using low speed fans. This is not the point.).

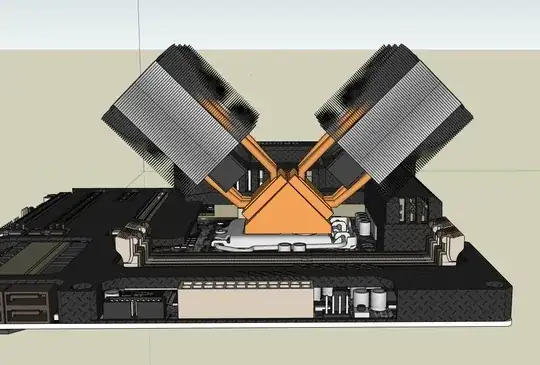

I came up with the idea to install not one but two CPU coolers, of which in theory one alone should keep a high performance CPU cool only using natural convection, but not in practice. For this I thought of using a triangular shaped piece of copper, with thermal compound between each surfaces.

Will this improve heat dissipation compared to a single heat sink or is the thermal resistance of the copper block a problem? I sketched the idea below: