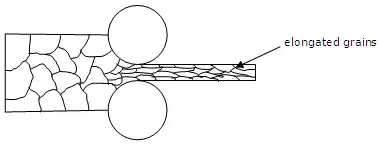

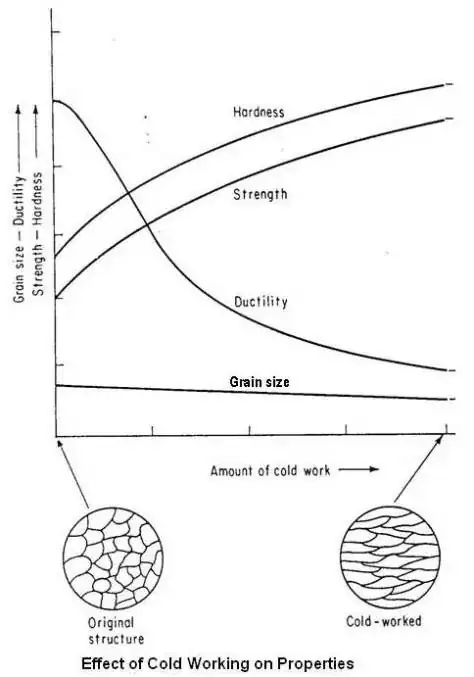

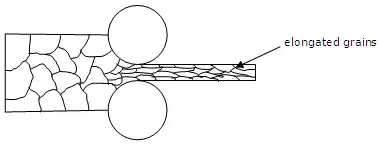

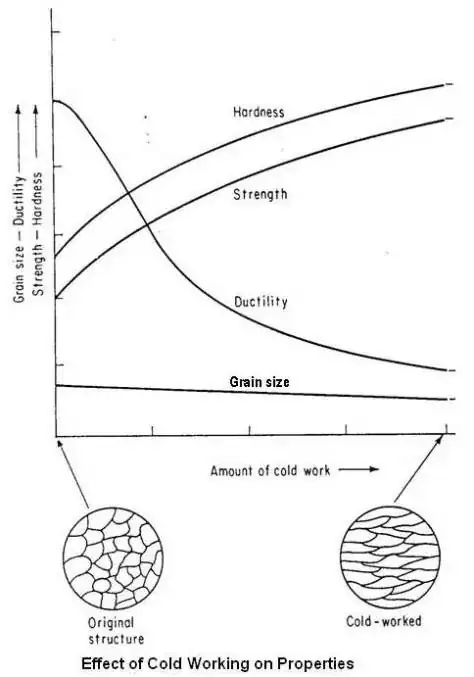

Every time you bend aluminium below the recrystallisation temperature, the macroscopic grains become smaller: this is known as cold work. The sides of the tab are either stretched or compressed. The effect is the same as the rolling example below. This is indeed a plastic deformation: the tab stays in place and doesn't bend back and stays in place.

Source

What you've just done is to make it harder for those grains to slip over each other, making the material harder and increasing it strength. You have however also made it a lot less ductile (and more brittle). If you bend a spoon, it's hard to bend it back to the correct shape. This is because that area has been cold worked and is stiffer than the surrounding metal.

Source

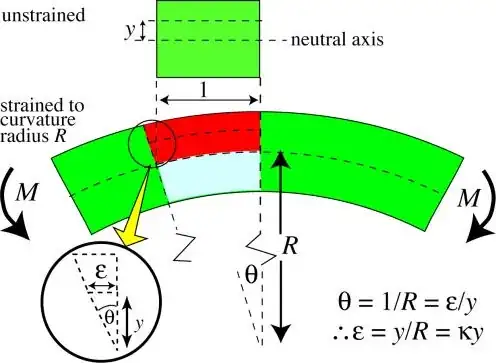

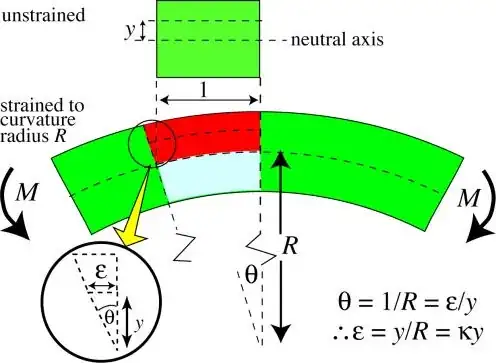

The same happens with your aluminium tab, except that there comes a point where it snaps. You can think of it like the beam below: You're bending it with a fixed deflection that corresponds to a certain angle θ. At some point as your ductility drops, you're going to go past the strain limit and it will snap.

Source

While it might appear to be fatigue, from an engineering perspective is really not the correct term to use. Fatigue is used to describe problems typically appearing after several thousand load cycles.