I'm trying to figure out how the heck some of these plastic bottle caps are injection molded. By having the thread on the inside of a cap, this obviously creates an undercut.

Now I've watched some videos on Youtube on the process, and I can see that a metal threaded core is twisted into place (automatically or manually by an operator). The mold is closed, plastic is then shot into it, the mold opens, and then the threaded core is twisted out of place to allow ejection.

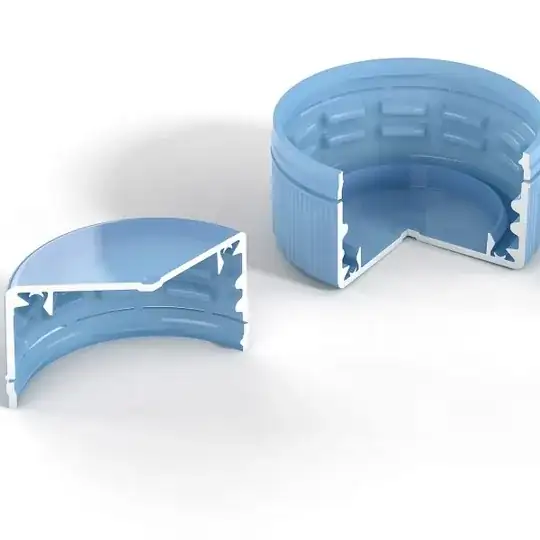

Some caps have split threads (as seen below) and use a collapsible core.

And some caps use a long continuous thread (as seen below) which makes sense for ejection (one continuous spin).

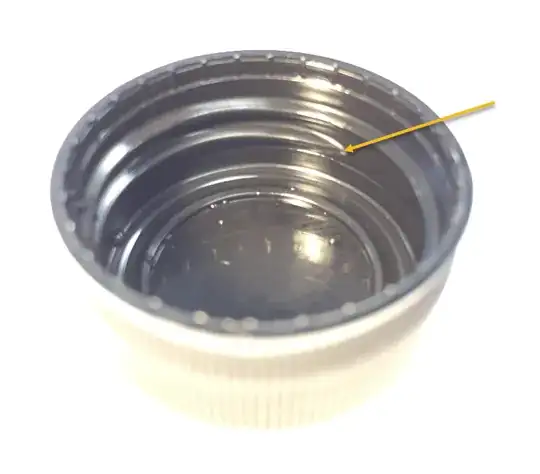

But this other style cap uses a long but non-continuous thread (as seen below).

My question is, how is this achieved? How does the threaded core spin out of place without colliding into the threads since the thread has an ending. In my mind, when this spins out of place, the feature on the core called out with the arrow below would collide into the freshly molded threads on its way out.