It is will known that most of tool steels are quenched in oil to prevent cracking and distortion which appears when quenching in water due to non-uniform cooling caused by formation of insulating vapor blanket "film boiling".

but according to some literature 1 using 14% brine solution or 1% polymr solution eliminate this vapor blanket so we can expecting more uniform cooling compared to water quenching.

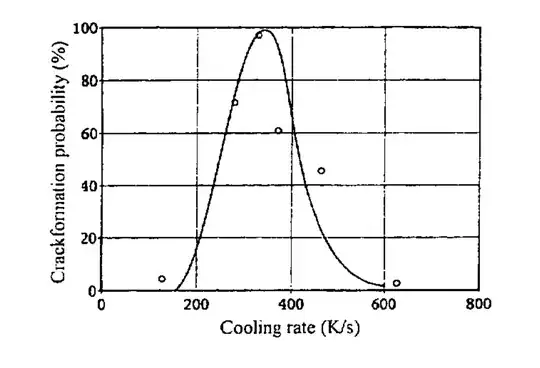

according to another literature 2 the probability of quench crack formation

at first increases to the maximum value, and then decreases to zero.

increasing cooling rate is possible by using strongly circulated brine quenching bath, and using brine eliminate vapor blanket which ensure uniform cooling.

so, can we excepting maximum hardening depth, minimal cracking and distortion and eliminated fire hazard by quenching high alloy tool steels by quenching in circulated brine instead of oil ?