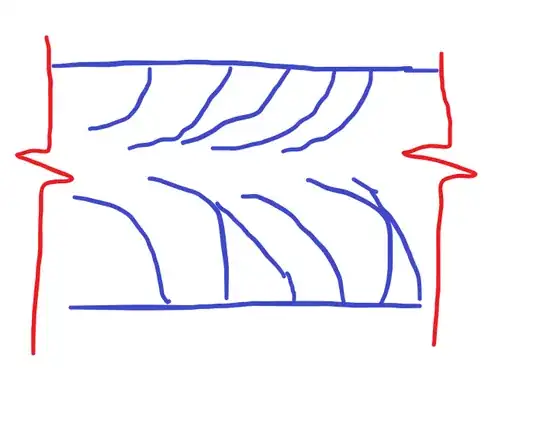

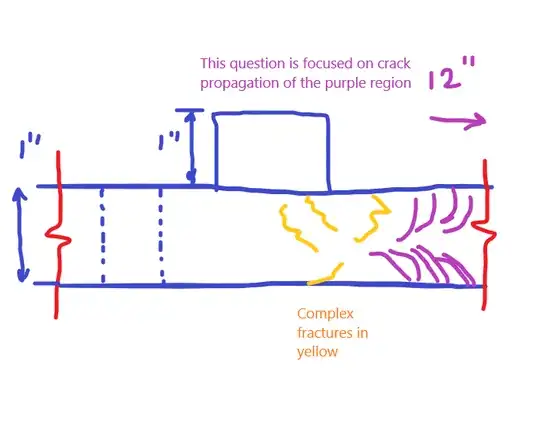

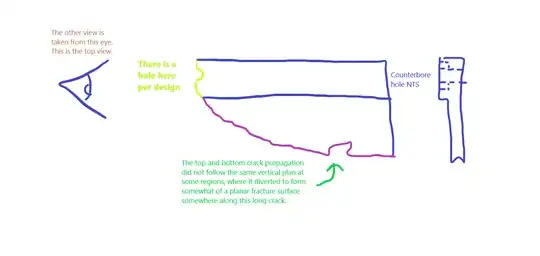

I have a scenario where we have encountered a cracked steel plate where the crack has propagated within the plate longitudinally for an extensive length. The plate thickness is 1", and the crack length is approximately 12" with somewhat of a bend horizontally, yet staying within maybe 3/8" max variation propagating right between the top and bottom of the plate. Stresses are complex but the highest load is likely a vertical load, and may be close to 10-20 tons. Impact factor typically ranges between 3.5-5.5 for this load case, but it is complex and not precisely known for the location for the crack, which is suspected to have received only perhaps loads upward to an impact factor of 2-3. Precise stresses for failure are unknown. Steels in question is 4140. Growth marks have been observed throughout most of the entire crack, with somewhat of a < shape, which seems to indicate that it cracked both top and bottom and then finally through perhaps? But that Seems strange that it would crack just right near the middle of the plate thickness for such an extensive length when loads are not applied linearly.

I would like to review the theories how the crack propagated based on the described observations. What can a < crack surface tell me? Can someone list that out and provide appropriate literature backup?