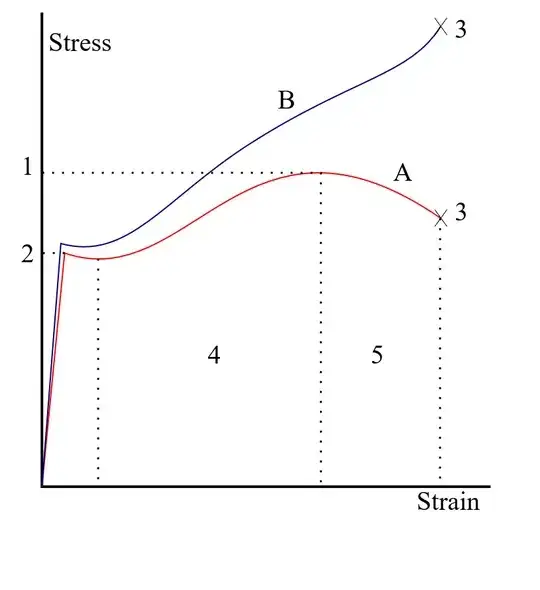

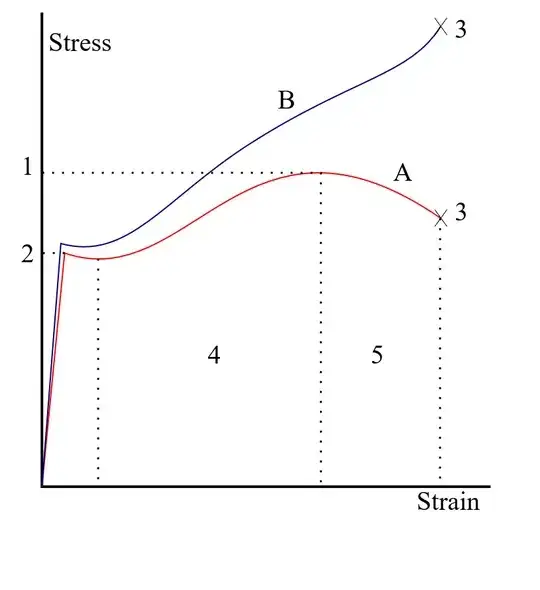

It just seems the way you mention because most of the books use the so called engineering graph. Which assumes the specimen surface area as constant throughout the loading which as we know is not right. Under tension the specimen extends axially and becomes narrower by the Poison's contraction.

So if we just plot stress versus strain curve without modifying the stress due to reduction in cross section of the specimen we get the known curve with straight elastic part and the large extension under higher stress due to hardening and the brittle rupture.

Because at the first point on the graph stress level the specimen is still ductile and has flexibility to accept even a little bit higher stress and keep stretching while it becomes harder and more brittle.

So after a large expansion it has lost almost all its ductility and it starts a sort of free fall elongation without increasing the stress and breaks at that point.

In reality there is never negative slope on the curve and it keeps rising albeit with different shapes at distinct stress levels.

The Wikipedia graph shows this, the blue curve,B, is the real and thered,A, is the engineering curve..

They explain this clearly here.Wikipedia Stress/strain