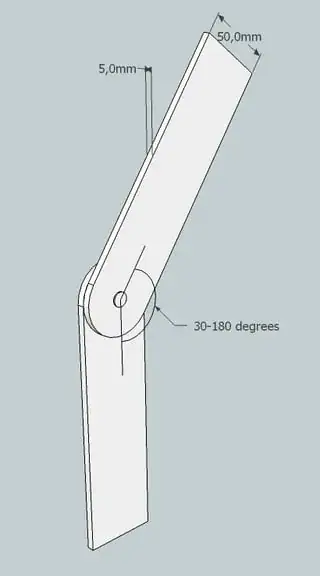

I need to connect two flat bars of metal with some kind of bearing that doesn't increase the joint thickness by more than 2-3mm (the less the better), as shown here:

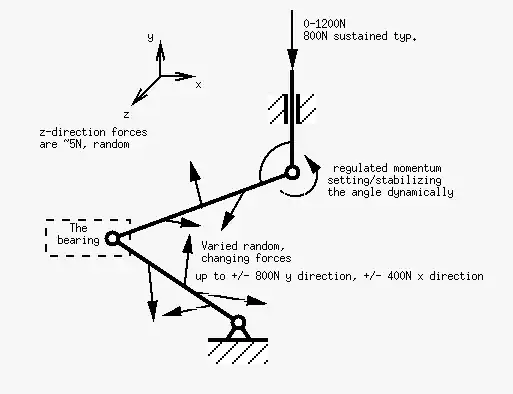

There are almost no axial loads but the peak lateral (shearing) stress on the bearing would be of order of 2000 N with 800 N sustained being the norm and the directions of the stress varies (although axial respective to the lower beam would be most common and strongest).

There is a serious restriction on thickness of the joint - the present 10 mm is already pushing the envelope; another 2-4 mm would be acceptable though unwelcome.

The bars will be steel or duraluminum. There are extra braces, etc., which prevent buckling and limit stress in the perpendicular direction to negligible levels, but the two bars need to carry axial stress and lateral stress "in the thick direction".

Moderate friction is acceptable - 5 N·m friction torque is still a reasonable value. Rotation is moderately fast, at most ~1 rev/s, usually much less. Also the range of rotation is limited; only 30-180 degrees angle between the two bars is needed (and even a little less than that if necessary). Lifetime doesn't need to exceed 1000 hours; less for the prototype.

This will be prototyped using a common DYI workshop without specialized machinery like CNC devices, also preferably no very expensive solutions - of course purchase of a pre-made bearing fitting the criteria would be perfectly acceptable if the price is not excessive.

What kind of bearing or joint would fulfill these prerequisites?

EDIT: Let me add a picture explaining the general layout of forces:

In general situation any common bolt, bushing (with flanged axis) etc. would be sufficient. Here the problem is getting it all to be narrow enough not to extend way out of the narrow plane occupied by the two bars, and not fall apart.