Background

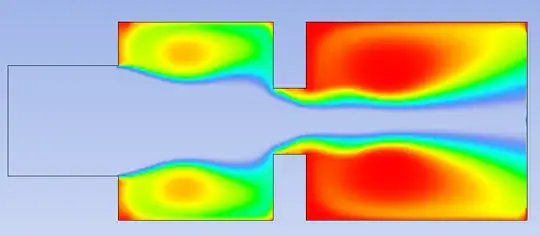

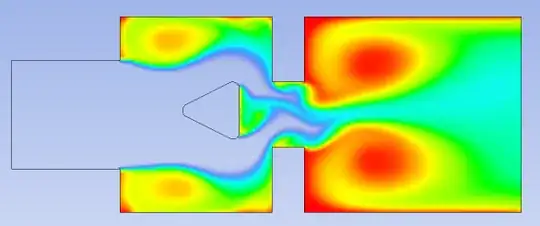

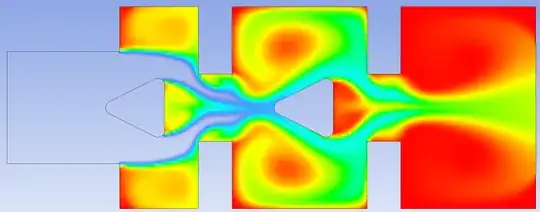

This is the standard design for a thermal furnace used in the Clauss process, which converts H2S to SO2. The main problem with the furnace is that gas mixing is rather poor and results in only a 60% conversion rate. This in turn increases downstream equipment costs to handle the impurities. A design improving the mixing of the gases is highly sought after.

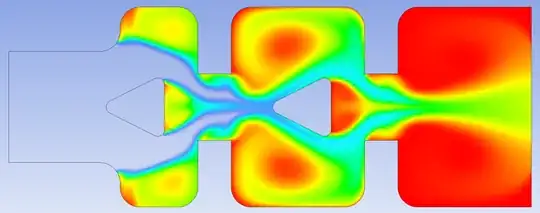

H2S and O2 is fed separately into the reactor. The combustion reaction starts and increases temperature to about 1400 °C. The choke point in the centre of the reactor is there to force the gases to better mix on either side of it.

What I have done thus far

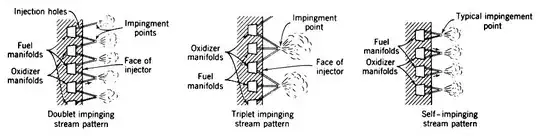

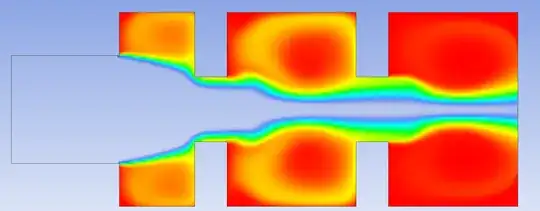

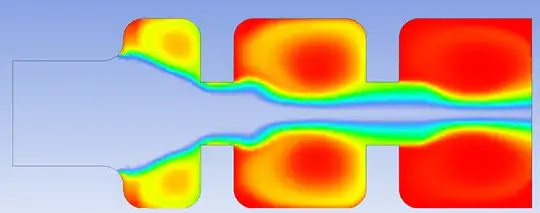

I have a design modification on the injectors that allowed much greater mixing, with inspiration taken from fuel injectors in motor vehicles.

I did not include the choke point in this drawing. It was merely done to test the validity of the concept.

The twice-angled injectors provide horizontal as well as radial velocity to the inlet gases. This causes a swirling effect on the fluid, improving mixing by about 60%. Mixing is here defined as the homogeneity of the outlet product distribution.

The advantages are two fold: The gas particles need to travel further due to the swirling, increasing the time they stay in the reactor. Thus, a larger conversion is also achieved, or viewed from a different perspective, a smaller reactor is needed to achieve the same conversion as the standard unit, dramatically reducing costs.

The question

I wish to exploit certain fluid dynamics phenomena to improve upon the mixing. Eddy formation, for example, is used in the choking section. What else can be done to improve mixing? What features can be added/removed?

PS: Explain your proposed design in words, no need for actual modelling.

Of course, it would help me to see the idea, but it is not necessary.

I have access to Fluent in which I simulate these designs and compare them to the standard unit.

I am still eager to see what you can come up with.