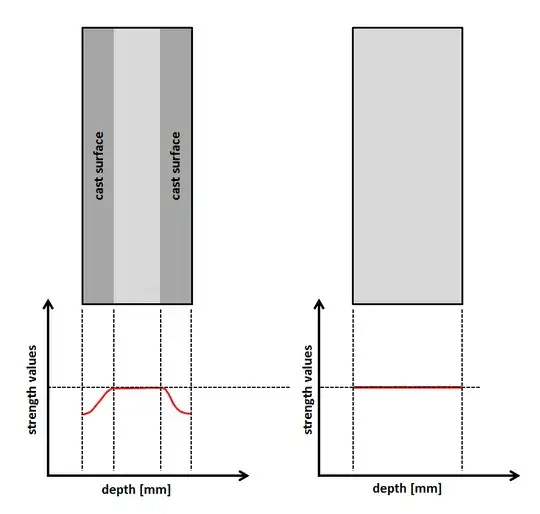

While my research about the untreated surface of moulded cast I read that the properties such as tensile strength, 0,2% proof stress and so on are different (much smaller) from the properties you can find in the tables. That’s because the samples have a treated surface to evaluate the material properties.

Now my question is how can I determine the thickness of the surface where my properties are much smaller?

The background is that I have a bore near the untreated surface loaded with hydraulic pressure and for safety I need a specific thickness of material around the bore. And because the material properties of the untreated surface are much smaller, I will not take this area into account to my calculations. If it is needed: the regarded cast is GJS 400.

Many thanks in advance!