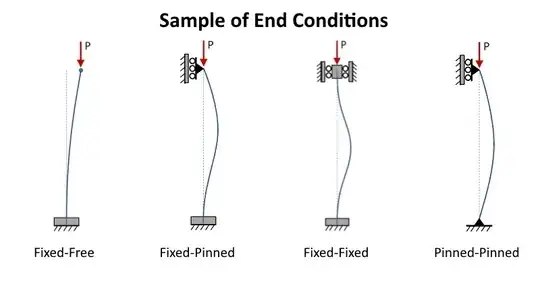

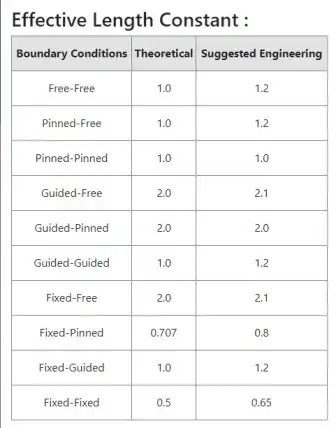

I'm trying to do some calculations for a personal project. I'm trying to understand column strength / buckling. My questions relate to Effective Length Constant, which is based on Boundary Conditions (how the ends of the column are restrained) The four choices there are: Free, Fixed, Guided or Pinned:

And different end conditions affect the Effective Length Constant, used in buckling calculations:

(edit.. ref: source for the above Length Constants)

But my dilemma is I'm intending welded metal tubing without corner gussets. I think with a gusset (and / or with cross bracing straps), I'd use Fixed-Fixed calculations, but simple butt welds that's not so clear.

Does anyone have testing data or other experience on how to address end conditions for buckling calculations with a simple welded butt joint at the ends of a column under load? <---- Here is my question for this posting...

And just for reference, the kind of thing I'm investigating is a drive on vehicle ramp. Obviously lighter is better for handling and storage... And yes I'm thinking astronomically large safety margins, but I'd like to know the real load capability numbers.

Note: related reference.

Again, how does one address end conditions for welded in place column materials?