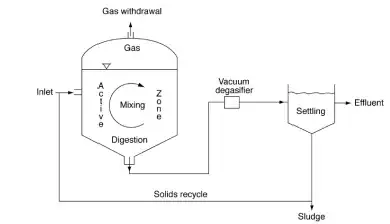

There are high-rate anaerobic digestion systems where you remove substrate from the digester, let it settle in a tank, and pump back the settled sludge (possibly not all of it) to ensure a higher sludge retention time.

One problem with settling of sludge is that the forming of gas bubbles prevents settling. So before the settling tank, there's a degassing system. This is a basic PFD of such a process:

Image source

How do these degasifiers work? What are their operating principles?