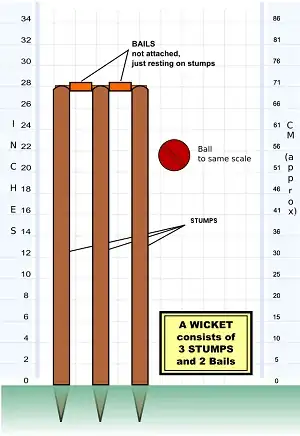

I am planning to replace the material that is used for Cricket Stumps. Cricket is a game similar to baseball. One difference is the presence of 3 successive stumps between the hitter and catcher. The ball will hit the stumps if the hitter misses it. The combined weight of the stumps is 7 lbs. Each stump is a 28 inch long wooden cylindrical stump of 1.5 inch radius weight 2.3 lbs. The stump can be hollow inside. As of now the regular stumps are made of solid wood.

I am in search of a lightweight alternative for the wooden stump. The material should be able to withstand the force of the ball which typically travels at 80 mph.

Is there any cheap and lightweight plastic material that can drastically reduce the weight of the stump and still withstand the forces mentioned above?