I was wondering if it'd be a good idea to attach a 10kg load to the end of a movable steel rod by fastening it with just one M5 bolt. Looking at Misumi's datasheet, M5 (Class 10.9) has an allowable load of 111kgf. 111kgf is 10x more than my requirement for static load. However, it's not quite clear if 111kgf is for both axial and radial directions. If the load was de/accelerated in any direction, would an M5 bolt be able to support that? For a 10kg load, does that mean if the de/acceleration of the load stayed below 10*9.8m/s^2 = 98m/s^2 (by F=ma), then a single M5 bolt would still be OK? Perhaps if the load was allowed to swing as well, the centrifugal force wouldn't be too far off?

Any guidance would be greatly appreciated.

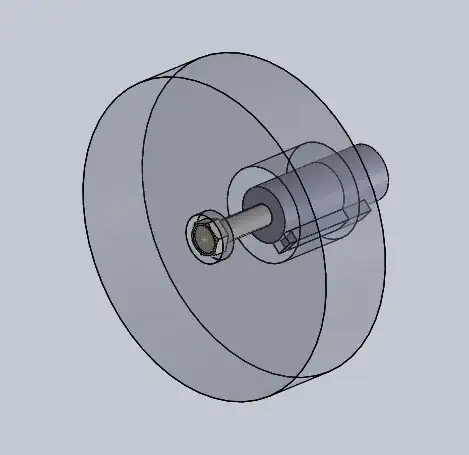

EDIT1: Here's a diagram:

EDIT2: Here's a revised version: