So i want to have a reel (~4cm diameter) that will pull a ~80cm string with a torque of ~8kg-cm (edit: thanks for the clarification). To pull I want to use a gear motor. E.g. 12V DC motor like this:

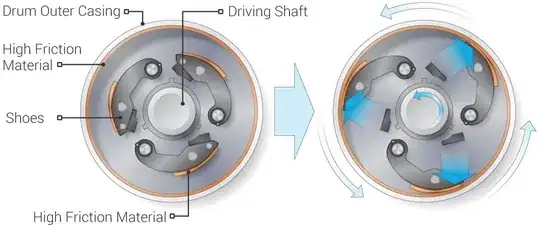

The problem is that I want to be able to easily unwind the string with my hands when the motor is not pulling in the string. So I would need some kind of possibility to disengage the motor. The problem is something like a sprag clutch (or one-way bearing) would not work as I pull the string in the opposite direction of the way the motor would spin. I found something like the "freecoaster" designs for bikes, but I don't know how I could build this cheap and easy especially given the small form factor (and limited tooling: mostly a 3d-printer, and normal tools). My other idea would be to try and create some kind of clutch that i would engage using a servo motor, by sliding a clutch like this on the axle using a servo motor. But I am not sure how well that would work or if there is a better alternative.

So what would be your suggestion to create a system that allows me to engage the motor to a free spinning spool when I need it to wind the string.

This motor will only be used to pull in the string once every month or so, so it doesn't need to be able to withstand thousands of cycles. But when it is used, it should work relatively reliable. I also found this question that seems to try and solve a similar problem. But I don't know how well that would work for my usecase. Thank you for your help!