I'm a total novice and self taught, currently designing and building a workbench for woodworking with an adjustable height top. This is the last major part to finish and I'm having trouble determining which bearing configuration to use.

EDIT: I essentially am trying to do this, except with the drive mounted below the floor instead of over it: https://www.youtube.com/watch?v=URrEdGeoDBs

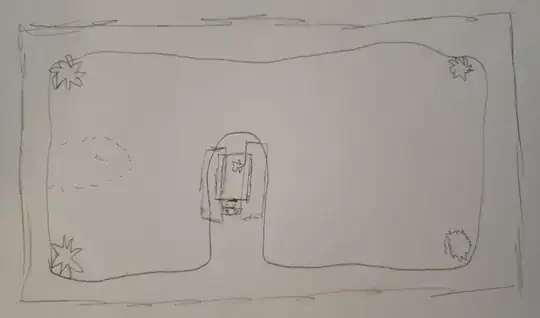

Overview: There are four legs (4x4s) that travel in a cuff. I'm designing for the top to carry and lift about 400lbs, but more likely will be under 100lbs (with each leg being able to lift 100 lbs max / 25 lbs). Total amount of lift is going to be between 15-17" depending on the bearing configuration. After the bench is lifted to different heights, I'll have spacers to hold it in place and then back off the force of the lift (so if I'm hammering something, I won't be hammering against the threaded rods)

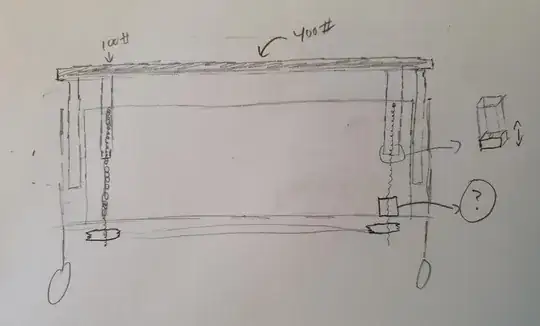

The rising mechanism is driven by four threaded rods (3/4"). Below the table, each rod will have a gear, and all four will be connected by one roller chain driven by one drive gear (which I'll use an electric drill to turn). On the threaded rod is a square nut, that fits inside a square tube held in place by two tension pins (so as the rod turns, it will push up against the tension rods/square tube which pushes the top of the workbench up and down).

Some sketches:

- Underneath view with gears and chain: http://prntscr.com/uf1bup

- Front view, leg cuffs, threaded rod / square tubing. Bottom right, the bearing issue (see the "?"): http://prntscr.com/uf241j

Problem Description and Research:

- Because the gears must be located under the bench (the inside of the bench is used for some tools and whatnot), I need a way to brace the forces of the rod/workbench top against the bench floor.

- From what I understand, radial bearings are designed to handle perpendicular forces to the shaft, while thrust bearings are designed for mostly axial/thrust forces parallel to the shaft. Also, the more hardware I have above the workbench top, the less rise I can get, so being really economical with what I use above the workbench is important.

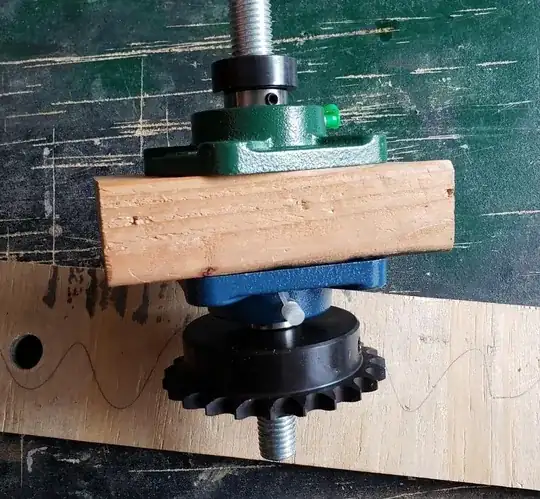

I bought a bunch of different radial and thrust bearings to try out an assortment of options, they all have pros and drawbacks. (For underneath I'm using a flanged bearing along with the gear and collar clamp to hold it in place, I'm struggling with the above floor bearings unless you have other ideas on the underneath part)

Option 1): Flanged / pillow radial bearing. https://www.amazon.com/gp/product/B01NCUJH8I/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 These bearing are rated for Static (axial) Load Rating: 6.65 kN/1500 lbs and Dynamic (radial) Load Rating: 12.8 kN/2900 lbs. On the pro side, the flange plus set screws will allow me to hold the threaded rod in place, along with a collar it should hold well and not slip. Con, I don't think this is the right kind of bearing. I tapped one with a hammer and it started to come out of the race a little...but maybe for these types of lifting forces it'll be fine?

Prototype picture: http://prntscr.com/uf1sa9

(2x4 represents the workbench floor, flange bearing above with collar above.)

Option 2): Thrust Bearings. https://www.amazon.com/gp/product/B01EBKYSWA/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 If I use thrust bearings, which seem to be the correct type of bearing to use, they bind and rub on the floor of the bench because the inner race is proud. I've tried drilling a wider hole, but the tolerances are too tight to solve the problem. I feel like there's a configuration that this could work but I've spent days playing with different types and haven't found a solution.

Quick prototype pics:

- Recessed bottom plate: http://prntscr.com/uf1u9y

- Thrust bearing: http://prntscr.com/uf1vsp

- Thrust bearing and collar (this is rubbing despite the recessed bottom): http://prntscr.com/uf1uy5

- Using the race from one as a bushing (this works, but I feel like there must be an easier way and uses up a ton of real estate): http://prntscr.com/uf20rx

Option 3: I also have a bunch of these radial bearings...but pretty sure they're not the right type for this application? http://prntscr.com/uf22dd

So, should I go with Option 1, 2, 3, or is there another / easier configuration that would make a lot more sense? If you know of a better bearing design a link would be really useful as a visual as well.

Thank you!