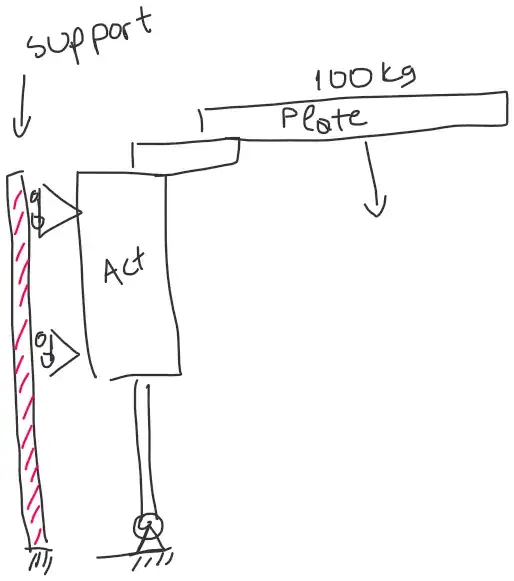

Does anyone know if this would be a good idea?

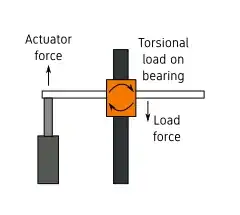

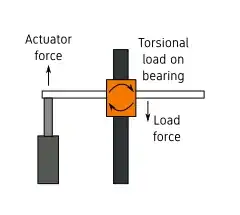

The proposed design has poor rigidity towards torsional loads. It doesn't matter whether the actuator is off-center or if the load is off-center: if load's center of gravity and actuator are not at the same position, the torsional load will likely damage the bearings.

In your example with two guide rails, torsional loads try to rotate the two linear bearings. The bearings are not usually designed to take much load in this direction, and some are in fact designed to be compliant of small rotations (alignment errors).

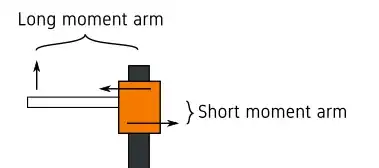

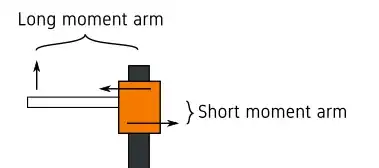

You can think of it like this: the actuator force is pulling on a long moment arm, while the bearing forces have a much shorter arm. Therefore the bearing has to handle many times larger force than is actually needed to keep the platform up. In your case of 100kg load, the bearing force would likely be hundreds of kilograms.

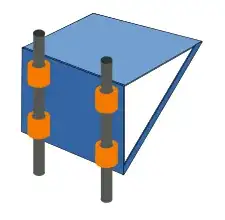

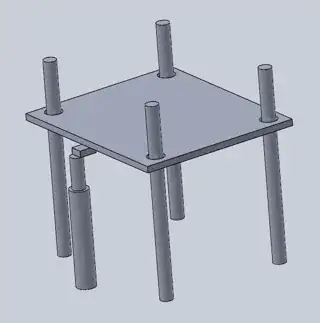

The example with four guide rails is slightly better in that it has half the load per bearing because there are four of them. Because they are all in the same plane, the lever advantage is equal as with two guide rails.

Would the linear actuator wear out more rapidly if the actuation was off-centre?

If the linear actuator is rigidly connected, it might take some of the torsional force on itself and wear out its internal sliding surfaces more rapidly. But the best practice is to connect linear actuators in a way that does not transmit torque. In fact, most linear actuators (random example) have only a single mounting hole at each end. Such a mounting prevents premature wear on the actuator - it would be the guide rail bearings that would break or wear out.

kamran's suggestion of a scissor lift mechanism is a good choice, especially considering the quite large 100 kg load. The diagonal arms of a scissor mechanism transfer the torsional loads to the support of the scissor arm ends.

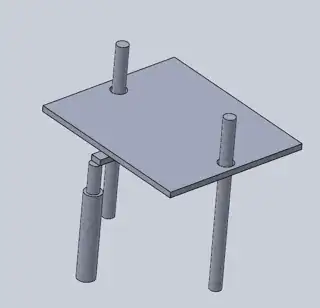

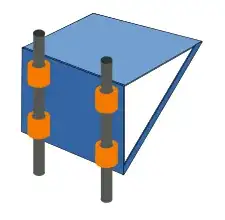

There are however other alternatives also. For example, one can mount four bearings on two guide rails like in the picture below. Now the moment arm for bearing forces is approximately the same as the moment arm for load forces, and horizontal load on bearings is thus smaller. The actual location of the actuator is not very important, as it only requires correctly sizing the guide rails and bearings to handle the load.