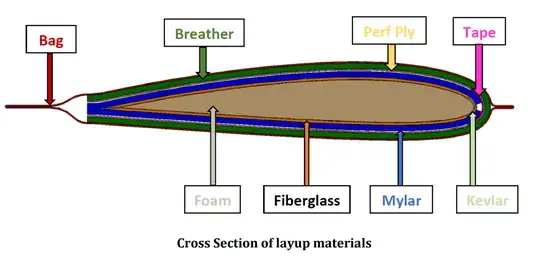

During my work at a composites workshop I got some experience with composites and vacuum-bagging. I decided to make a foam core wing for a model aeroplane. I checked for some internet info on it, and what I found is that instead of the classical arrangement we would use at the workshop:

- core

- impregnated fiber layers

- perforated peel ply

- breather layer

- vacuum bag

In wing vacuuming guides, they put an additional layer of Mylar between the fiber layers and the peel ply. The Mylar is removed after curing.

Why do this? Is this to have a smoother surface for the wing? Mylar can be used to efficiently contain gases (baloons, food industry etc). Wouldn't this mean that it also blocks the excess resin that should go trough it? Or if I assume that resin can go trough the Mylar layer freely, then what's the point of having a perforated peel ply at all? Is the Mylar layer essentially doing the work of the peel ply?