The "printing" mentioned is actually an important aspect of the fabrication of microchips. Similar to printing a T-shirt or poster, the entire t-shirt is made at one time - you do not want to have to drawn each pixel one at a time.

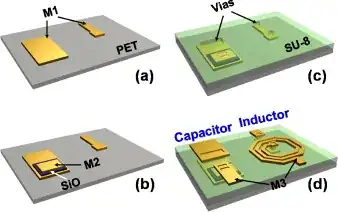

Similarly microchips use printing techniques that pattern many components - transistors, capacitors and resistors - at a time. However, they do so layer-by-layer, similar to 3D printing for example (with the huge exception that 3D printing touches every pixel one by one, whereas chip printing patterns a large area at a time).

Here is an example fabrication flow of a simple NMOS transistor (on FabuBlox):

Although this shows only one transistor, these steps are performed on an entire wafer (eg. 100mm circular area), meaning each step is making 1000's of transistors are a time.

The main steps you can use are (not only in this specific order):

- Patterning with Photolithography

- Adding material with deposition or plating. Coats entire wafer.

- Removing material with Etching. Removes only where photolithography has not protected.

- Repeat some sequence of the above steps with different patterns and materials to build up the desired 3D structure.