The AISC 360-10 Specification for Structural Steel Buildings gives provisions for calculating the maximum unbraced length of a compression flange that separates yielding moment from lateral torsional buckling (LTB). This formula is (AISC 360-10, Eqn. F2-5):

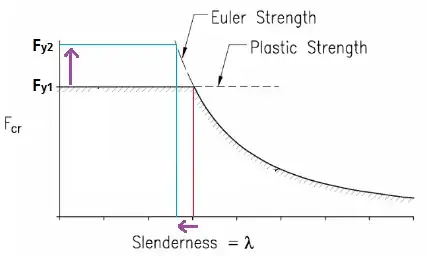

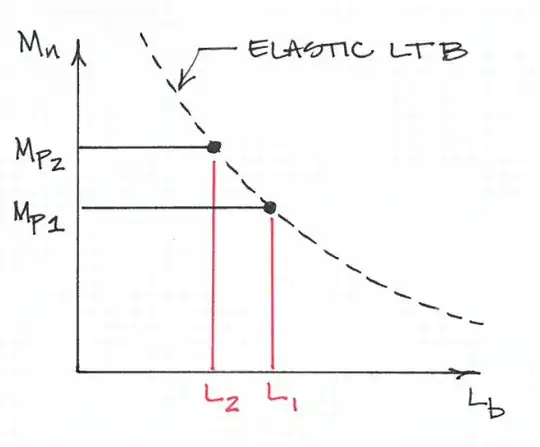

$$ L_p = 1.76r_y\sqrt{\frac{E}{F_y}} $$

where

$L_p =$ limiting length that separates full yield moment and LTB

$r_y =$ radius of gyration about the $y$-axis

$E =$ Young's modulus

$F_y =$ yield strength of material

Assuming that one is using regular structural steel, the Young's modulus of the material is assumed to be the same regardless of steel grade.

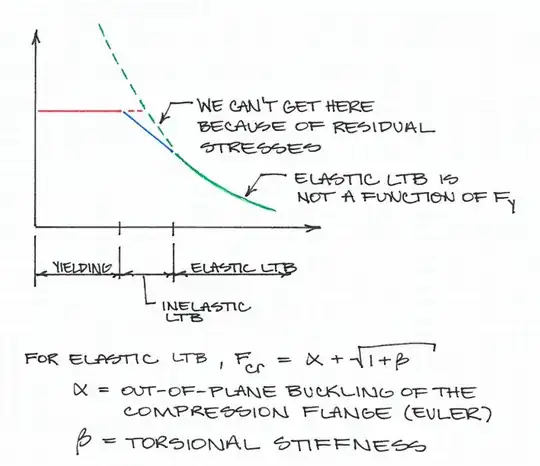

This equation works out such that a steel with a lower yield strength may actually be braced at a lesser interval than one with a higher yield strength. In other words, given the same beam size, the material with the higher yield strength buckles first.

I have also found this to be applicable to design using the ASME Boiler & Pressure Vessel code, specifically Division III, Subsection NF for supports. With temperature effects on yield strength and Young's modulus taken into account, it's possible that a member at an elevated temperature may buckle at a longer length than one at room temperature.

This seems counter-intuitive to me. Why would a weaker material exhibit less LTB action with the same given length?