Another way to approach is to determine the properties that influence the specific problem at hand. I'll give an example and you can see if it works for you.

Define the problem.

Lets assume that you want to determine the most appropriate material for the tensile testing of a bar of length L (with a uniform cross-section), and safety factor N, so that the weight of the bar is minimum.

From this problem you have the following specifications:

- Geometric

- Material

- $\rho$ material density

- $\sigma_{UTS}$ material strength

- Functional requirements

- F: maximum tensile force

- $N$: safety factor.

Determine the crucial parameter

The mass of the material is given by

$m = \rho \cdot L\cdot A$

The cross-sectional area A required to transfer the force will be given by:

$$A = \frac{F\cdot N }{\sigma_{UTS}}$$

Substituting, A to the mass equation you obtain

$$m = \rho \cdot L\cdot \frac{F\cdot N }{\sigma_{UTS}}$$

Now you can rearrange the formula as follows

$$m=\underbrace{F\cdot N}_{\text{Functional}} \cdot \underbrace{L}_{\text{Geometry }} \cdot \underbrace{\frac{\rho}{\sigma_{UTS}}}_{\text{material}}$$

From this you can see that in order to minimise the mass for this type of loading you need to minimise the ratio $\frac{\rho}{\sigma_{UTS}}$ or equivalently maximise the ratio $\frac{\sigma_{UTS}}{\rho}$.

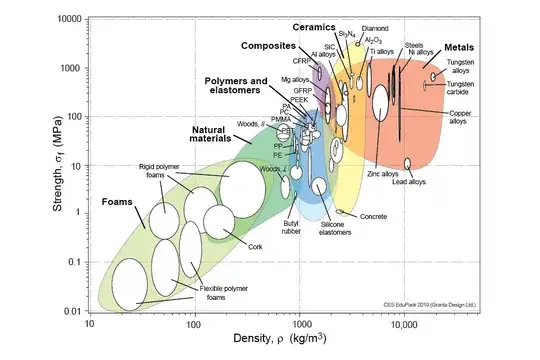

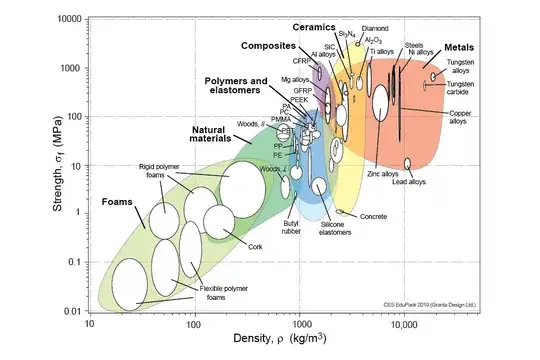

Then you can look for Ashby diagrams for Strength - density and find out which material is the most appropriate.

Other examples

You can follow the same pattern and you can for example:

- Determine the material properties to minimise the deflection given a specific mass.

In that case you would end up with material index $\frac{E}{\rho}$. Again you would look for an Ashby diagram for Stiffness - Density and select the most appropriate material

- Determine the material properties to minimise the cost of the material for a given deflection.

In that case you would end up with material index $\frac{E}{\rho\cdot C_m}$ (where $C_m$ is the material cost per kilo). Again you would look for an Ashby diagram for Stiffness - Density and select the most appropriate material

- Other loading conditions:

Things become more interesting when you consider buckling, bending or torsion.

final thoughts

Obviously this is tailor made to the application you have in mind. Therefore you are required to do some work depending on your problem. However, it is arguably a good starting point to categorize the materials based on the specific parameters of the problem at hand.

Of course, there are other parameters like workability, corrosion, toxicity that will remove some candidates, that need to be considered.