I made a test in Ansys but the result doesn't seem to be the final steady state. The two bodies didn't touch each other. How can I get the right result?

2 Answers

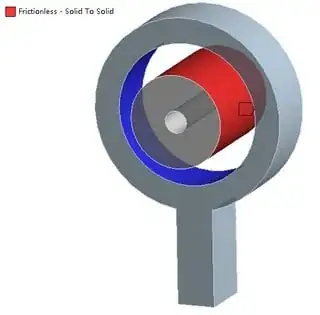

Okay so I ended up having a play in ANSYS Mechanical Workbench. I did a mock up of your problem. Here's how I've been able to successfully model it. Note that a lot of my decisions are based on the Contact Best Practices Guide from ANSYS.

Here's some very important points given your problem but also for contact modelling in general and a frictionless contact type:

As stated by Trevor there's no need for such a large gap initially - you don't need ANSYS to simulate that sort of behaviour because it should be obvious. So move the roller closer to the ring. I ended up moving the roller within 1mm of the ring. Just doing this on its own, however, isn't enough to get it to converge.

Mesh $\rightarrow$ Advanced $\rightarrow$ Shape Checking $\rightarrow$ Aggressive Mechanical (This is generally a good idea for any contact modelling).

After selecting the contact type as frictionless look under Advanced $\rightarrow$ Formulation $\rightarrow$ Normal Lagrange. It has highest accuracy of all the methods, can handle large sliding and interference fit. If you use Augmented Lagrange with frictionless it's likely to diverge when the contact is over a small surface area like your problem. On the other hand if you were considering a bonded or no-separation contact type then Augmented Lagrange formulation seems to converge well.

Frictionless Contact $\rightarrow$ Advanced $\rightarrow$ Interface Treatment $\rightarrow$ Adjust to Touch (should be obvious why I chose this).

Frictionless Contact $\rightarrow$ Advanced $\rightarrow$ Pinball Region $\rightarrow$ Radius. Set the radius to be at least as large as the gap between the surfaces.

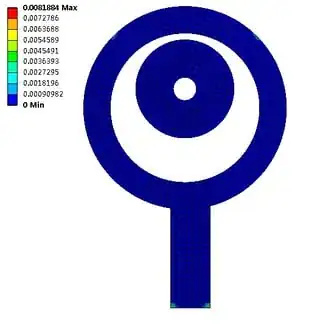

Below was the deflection result (left) and Von-Mises Stress result (right). As you can see the stress distribution is not great - around the contact area in the ring there are probably large stress concentrations. You might need a better mesh around the contact area as I spent hardly any time meshing. The main reason for this exercise was to prove that even though there is a gap between the contact surfaces there's appropriate controls in place to model it:

If you're expecting large deflections then you can turn ON "Large Deflection" in Analysis Settings $\rightarrow$ Solver Controls $\rightarrow$ Large Deflection. That might help it converge.

If you're wondering whether you could do this without moving the roller closer to the ring then you could probably play around with the Pinball Radius as well as another option called "Predict For Impact" in the Time Step Controls. I've never used this personally and I'm not sure what effect that would have.

If you have the time, read the best practices for contact modelling.

- 1,217

- 9

- 11

Unless you're trying to use ANSYS to validate common-sense/newtonian physics then start the analysis with them already touching.

- 386

- 1

- 6