Note: I understand the very nature of this question is about gross approximations on an incredibly complex topic, but even educated 'guesstimates' would be very helpful

I have already seen these two questions but i'm hoping with some provided data I can get some better insight.

I am experiencing constant mechanical vibrations in my bedroom from an unknown source somewhere in the building. They only last for 20-30mins then stop, but are an issue at night. It is the vibrations and not an actual noise causing issue. I am using vibration dampeners under my bed. I have tried 5 different products, with varying success. The current ones I am using seem to be 'styrene butadiene rubber' (medium hardness) with 'EVA polymetric foam' material' sandwiched between. Out of all the products so far, they are the softest and seem to have the best damping, although it is not enough.

However, I believe that all the products I am trying are still too hard for the frequency of the vibrations.

This idea is making me explore purchasing sorbothane disks (part numbers 0510435-30-10 or 0532350-50-10) with a 'duro' of either 30 (softer) or 50 (harder). I have found these spg and edg PDF files which show vibration damping calculations.

I am not an engineer and unfortunately I do not know the Hz of the vibrations I am experiencing. However, I can say it is akin to a washing machine near the end of a wash cycle on fast spin dry rather than a rumbling train.

The bed including myself and my partner weighs ~180 / ~200kg. The bed does not have four posts but a solid headboard and footboard which both reach the ground. This allows me to place more than 4 anti vibration pads rather than just one at each corner.

I am deciding between the two disks below (Imperial units listed);

0.25" Thickness x 2.25" Diameter (Duro 30, softer) 40lbs - 90lbs Load

6 Disks would give a max load of 244Kg (6 * (90 / 2.205))

0.50" Thickness x 2.25" Diameter (Duro 50, harder) 40lbs - 85lbs Load

6 Disks would give a max load of 231Kg (6 * (85 / 2.205))

So my main question; is a softer but thinner material better suited to absorbing high frequency vibrations than a thicker but slightly harder material?

From this answer, it implies that softer is better, but there is no mention of thickness.

And a bonus question;

Is it generally better to try 4 points of contact rather than 6? (thinner and harder, but two less points of contact) or should i actually try to increase the points of contact in order to use a softer material to dampen the vibrations?

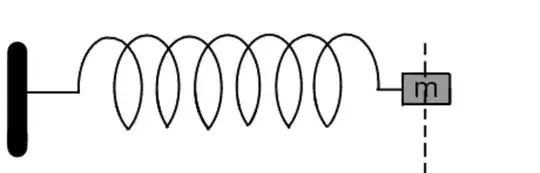

EDIT: I have a response from one of the product development engineers from sorbothane who advises to go for a thicker part since thicker parts will have lower natural frequencies.

As to not waste the question, perhaps someone can answer why that is in either basic or technical terms.