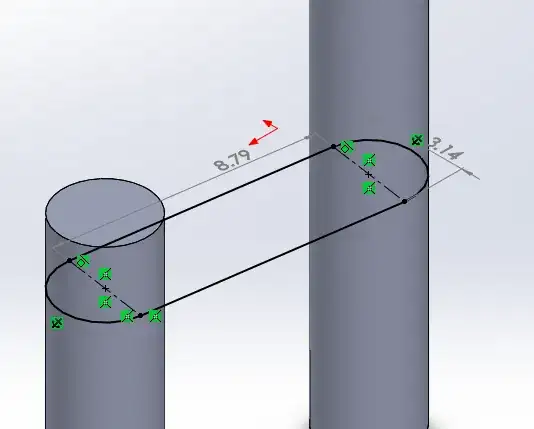

I am here regarding a personal project but I am not a mech engineer. The shaft is a watch stem that is displaced from the crown stem. The two shafts are positioned like in the photo below but are 0.9mm in diameter and about 2mm to 4mm apart (it can vary). The shafts can be threaded too. One of the shafts rotates and drives the other and it also can be pushed and pulled along it's axis a distance of 1mm and the other shaft needs to follow that.

I have considered a universal joint with a third shaft/rod between the two, but they cannot be sourced at this size and are hard to manufacture and I am not not certain that the linear force will transmit well with a steep angle.

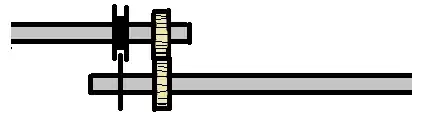

The other option is use an ordinary gear on each shaft for the rotation. And then couple the linear motion of the shafts with a metal bracket sitting around both shafts that is allows free rotation of the shafts but secures the linear motion of the shafts.

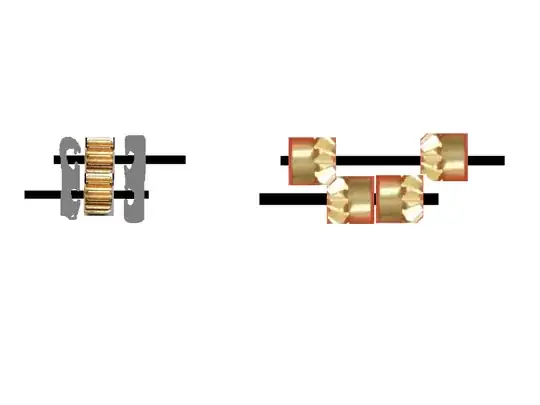

Another similar option would be to use 4 bevel gears. They would transmit the rotational power between shafts easily and the angled surfaces would restrict both shafts to the same linear movement.

Could someone help confirm this for me, I have no knowledge if this will work.