I have been thinking about small hydrostatic transmission to directly translate movement of stepper motor (NEMA 17-23 size, geared with 3:1 or 5:1 ratio).

My design currently involves 2 identical radial piston motors/pumps with 3 cylinders all connected to central crankshaft and individual hydraulic lines connected pair of cylinders (pump<->motor), so there are no extra valves, reservoirs, etc.

Each hydraulic line (3 in case of 3 cylinder pump/motor combo) is filled and purged separately, after that it should be (theoretically) sealed maintenance-free system able to precisely translate bidirectional movement of pump-driving stepper motor to actuator.

There will be obviously friction losses, but given that continuous power requirements for the whole system are quite small (4-5W) and the driving motor has safe max operating power level at least ~5 of that, it should be ok.

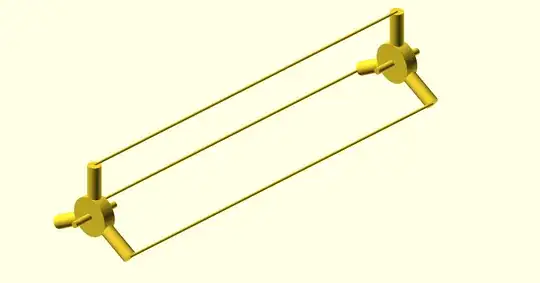

Rough sketch of the concept (pump/motor internals like conrods/crank not shown):

Do you see something obviously wrong with the design, why it won't work as envisioned ?