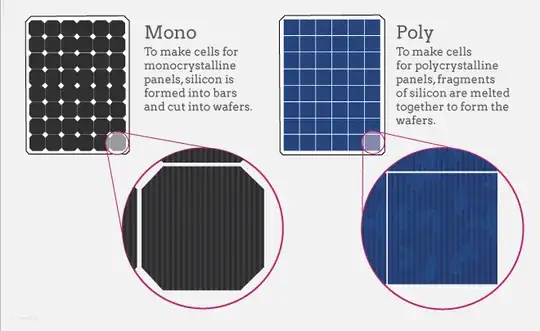

What is the meaning of this croped part? Why do they crop it, rather than let it be full square?

2 Answers

the monocrystalline cells are thinly sliced off cylindrically-grown single crystals that look like logs. Each wafer thus produced is hence a circular disc. To make the resulting solar cell function properly, its active area must be square so the rounded edges of the wafer get sawn off so the wafers can be packed together as closely as possible during bulk processing. The chamfered corners are left.

- 15,513

- 1

- 15

- 33

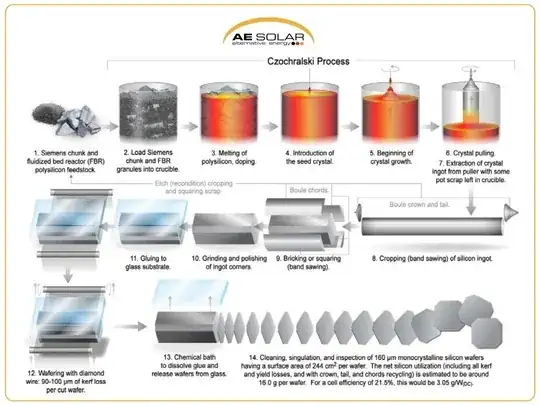

This question might be a bit old, but I think it is not too late to share knowledge to the world. You might be a bit confused by the first answer, but here I got some visual illustrations and hopefully clear explanation for you to understand why and how mono crystalline photovoltaic cells often has that rounded or cut corner look.

Mono crystalline cells are cut from a single crystal grown in a cylindrical log shape or "boule", which has a circular cross section. It is easy to think that manufacturers might cut corners for cost cutting or something else but that's not what is happening here. Before sliced into thin wafers, the cylindrical silicon crystal boule is cropped/bricked into square blocks just at the right spot so that the cells could be arranged compact enough to produce maximum possible energy without wasting too much space and also there won't be too much wasted material if cropped into perfect square. (The second reason is just my opinion, of course they could just recycle any unused material). If left uncropped, having circular disc shaped cells in a module not only weird but also wastes too much space for lesser efficiency due to the areas not covered by the photovoltaic cells. I'm sure there might be other reasons I didn't mention but this is what I know so far.

For your curiosity, of course there are actually some, mostly newer generation monocrystalline PV cells that doesn't have rounded corners. They're likely made of wafers from bigger diameter crystal boule cut into smaller cells.

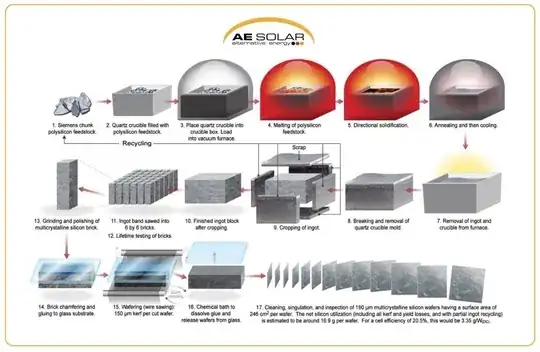

Here's an illustration of the manufacturing process of poly crystalline for reference and how they had that perfect squared cut without any corners cut.

All illustrations thanks to AE-Solar

- 121

- 2